Chains Nominal No.12B/Joint Link

Caution

- Download Free! >> Economy Series Catalog (TH-EN-FY25) CLICK here

Product Description

- Chains Nominal No. 12B/Joint Link from MISUMI.

- This chain type is economy series of standard chains.

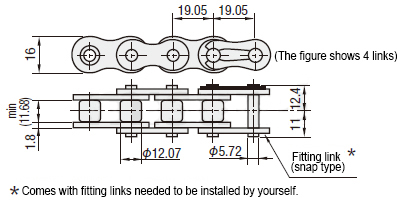

- Chain nominal No. is 12B while pitch No. is 19.05mm.

- Max. Allowable Tension of chain is 1.93kN.

- Can be selected fixed type which the number of chain links is 80 links, circumference length is 1,524mm. Or configurable type which can be configured 4 to 9998 links (2 links increment).

- Chains are made of steel.

- This series is ISO Standard 12B roller chain and can be used in combination with our 12B series sprocket.

Economy Chains Nominal No.12B/Joint Link

- The Economy Series roller chain delivers dependable performance for a wide range of applications.

- Choose between a fixed chain or a customizable length for flexibility in various industrial setups.

- Designed to standards ensuring perfect compatibility with MISUMI’s products.

- Made from high-quality steel, offering durability and longevity in demanding environments.

- Ideal for both power transmission and workpiece transfer, providing efficient performance.

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Product Overview of Chains

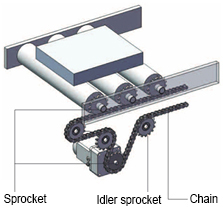

■Only sprockets and Chains with the same specifications can be used in combination.

This series is ISO Standard 12B roller Chains, and can be used in combination with our 12B series sprocket. Do not use it with American Standard or Japanese Standard 12A series sprocket, which may cause the chain sprocket mechanism to fail to function properly!

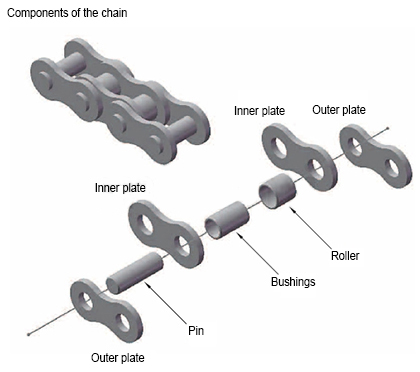

■ Product Composition

Dimensional Drawing of Chains

Material: Steel

Material: SteelSpecifications Overview of Chains

This series is ISO Standard 12B roller Chains, and can be used in combination with our 12B series sprocket.

Do not use it with Japanese Standard or American Standard sprocket, which may cause the Chains sprocket mechanism to fail to function properly!

Product Feature of Chains

1. Multi-tooth load bearing, safe and reliable;

2. Flexible transmission, absorbing shock and vibration;

3. Large center distance range, low manufacturing and mounting accuracy requirements;

4. Compared with belt drive, the transmission ratio is accurate and the transmission efficiency is higher, suitable for high temperature.

■Two main purposes of the Chains:

1. Connect the motor for transmission 2. Place the workpiece directly or indirectly on the Chains for transfer

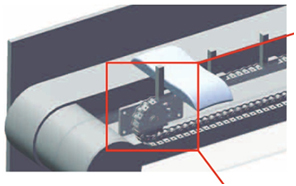

Example Use of Chains

A mechanism that can convert motor power into roller rotation by combining multiple sprockets and Chains

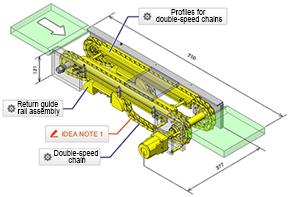

A chain conveyor frame with high versatility using flat profiles and Chains guides

A mechanism used to mount accessories on the Chains, and extract and transport workpieces

Precautions of Chains

If you need to cut the Chains by yourself, please confirm whether the chain link to be cut is an inner link or an outer link. If it is a single section after being cut off, it may need to be used with an offset link head.

Usage Method of Chains

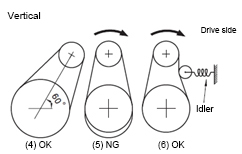

■Horizontal

Even when the two axes are arranged horizontally, the rotation direction of the axis must be considered.

The examples (2) and (3) in the figure show that when the Chains is stretched, the disengagement between the sprocket teeth and the chain is not smooth and may bite.

In particular, the upper and lower Chains in (3) will contact each other, so an idler is required.

If the Chains is stretched, slack as shown in (5) will occur, and

when a small sprocket is used on the lower side, the chain may fall off. Therefore, please use it at an angle of 60 or less as shown in (4).

When it is necessary to use it vertically due to the mechanism or space, it is recommended to put the large sprocket on the lower side, and

use the idler on the outside or inside as shown in (6).

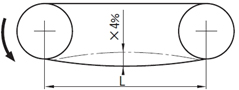

Deflection is generally about 4% of the shaft spacing, and about 2% in the following cases.

a. Vertical transmission or close to vertical transmission

b. Shaft spacing is more than 1m

c. When frequent heavy load starting and stopping are required

d. When reverse rotation is required

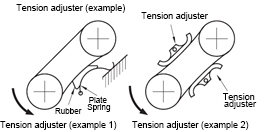

If a tension adjuster is mounted on the tension side or slack side of the Chains to provide initial tension in advance, it will eliminate vibration and reduce noise during operation.

Related Products of Chains

|

| Sprocket 12B |