Pivot Pins Straight With Retaining Ring Grooves

Caution

- Download Free! >>Economy Series Catalog ver2023 (TH-EN)_Part07 CLICK here

Product Description

・ Product type: Pivot Pins Straight With Retaining Ring Grooves, C-CDG series.

・ Shaft outer diameter [mm]: 3, 4, 5, 6, 8, 10

・ Overall shaft length [mm]: 8, 10, 12, 15, 16, 18, 20, 22, 25, 30, 35, 40

・ Hinge Pins is versatile pivot points for rotary connection mechanisms. Functions akin to hinge axes, enabling connected parts to rotate smoothly.

・ Material: Made of S45C with Ferroferric oxide protective film

・ This is an economy item; The price is cheaper than the MISUMI standard product.

Product Overview of Hinge Pins

Product Feature of Hinge Pins

Feature of Hinge Pins 2: About 50% cheaper than MISUMI standard (high quality) linear bearings.

Feature of Hinge Pins 3: Appropriate specifications can be selected according to the conditions of use.

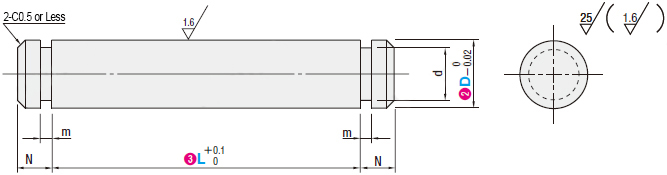

Dimensional Drawing of Hinge Pins

D tolerance is limited to the L dimension part, and others are general tolerances.

D tolerance is limited to the L dimension part, and others are general tolerances.Specifications Overview of Hinge Pins

| Type of Hinge Pins | D[Φ:mm] |  Material Material |  Hardness Hardness |  Surface Treatment Surface Treatment |  Accessories Accessories |

| C-CDG | 3~10 | S45C Equivalent | - | Ferroferric Oxide Protective Film | - |

The product of Hinge Pins does not come with a retaining ring. For retaining ring models, please refer to Dimension specification table.

The product of Hinge Pins does not come with a retaining ring. For retaining ring models, please refer to Dimension specification table. If there are requirements for rust prevention, give priority to high-quality Hinge Pins.

If there are requirements for rust prevention, give priority to high-quality Hinge Pins.Precautions of Hinge Pins

② Anti-rust specification selection and maintenance

If there are requirements for rust prevention, give priority to high-quality hinge pins.

Products without surface treatment need to be applied antirust oil regularly for maintenance.

③ This product of Hinge Pins does not come with retaining rings.

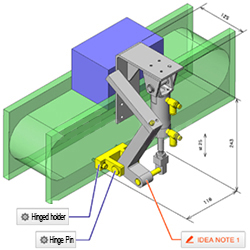

Example Use of Hinge Pins

Automatic Roller Shutter Mechanism

Design Purpose of Hinge Pins:

A structure that uses a cylinder to automatically open and close the shutter, and a thin cylinder presses the shutter to ensure tightness when it is closed.

Parts Application Description:

Hinge Pins and hinge base are used in conjunction to realize vertical movement of the connecting rod mechanism.

Application Industries of Hinge Pins

| Electronic & Electrical Appliances | Automotive | Lithium battery | ||

|  |  | ||

| Robotics | Smart phone | Semiconductor | ||

|  |  |

Related Products of Hinge Pins

| Adjustment Screw Components Hex Socket on Head | Single Bearing Type with Retaining Ring Embedded | Packed Gasket Ring Fixed/Gasket Ring | ||

|  |  | ||

| Typical model of Hinge Pins: ANB8-40 | Typical model of Hinge Pins: BGRR6000ZZ | Typical model of Hinge Pins: PCIMR6-12-0.1 | ||

| Advantages of Hinge Pins: manual adjustment and positioning, optional length | Advantages of Hinge Pins: full range, high precision | Advantages of Hinge Pins: full range, high precision and high quality |

Specification Table of Hinge Pins

| Type of Hinge Pins |  Equivalent material Equivalent material |  Hardness Hardness |  Surface Treatment Surface Treatment |  Accessories Accessories |

| C-CDG | S45C | - | Ferroferric Oxide Protective Film | - |

Dimension Specification Table of Hinge Pins

| Part Number of Hinge Pins |  L L(Fixed Size Selection) | m | N | d | Retaining ring | ||||||||||||||

Type Type |  D D | ||||||||||||||||||

| Tolerance | Shape | JIS Nominal Specifications | |||||||||||||||||

| C-CDG | 3 | 0 -0.02 | 8 | 10 | 12 | 15 | 18 | 20 | 0.5 | 2 | 2 | E Type | No. 2 | ||||||

| 4 | 12 | 15 | 18 | 20 | 1 | 3 | No. 3 | ||||||||||||

| 5 | 16 | 18 | 20 | 4 | No. 4 | ||||||||||||||

| 6 | 16 | 18 | 20 | 22 | 25 | 30 | 5 | No. 5 | |||||||||||

| 8 | 25 | 30 | 35 | 40 | 0.9 | 3 | 7 | No. 7 | |||||||||||

| 10 | 30 | 35 | 40 | 1 | 10 | C Type | No.10 | ||||||||||||

For JIS engineering specifications of the supplied retaining ring, refer to Retaining Ring Specifications.

For JIS engineering specifications of the supplied retaining ring, refer to Retaining Ring Specifications.