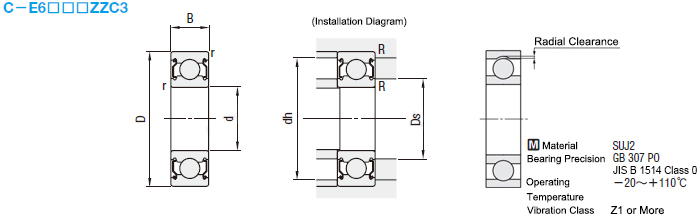

Ball Bearings C3 Clearance

Caution

- The requirements of vibration class Z1 of the industry are met at ultra-low price

- Download Free! >> Economy Series Catalog (TH-EN-FY25) CLICK here

Product Description

Ball Bearings C3 Clearance

Ball bearings with C3 clearance is commonly used in applications where there is a need for the bearing to accommodate thermal expansion or contraction. These bearings are available in various sizes to choose from.

[Feature]

● Bearing Size Standards: Metric System

● Inner Diameter Minimum / Maximum (mm.) : 10 and 50

● Outer Diameter Minimum / Maximum (mm.) : 26 and 110

● Width Minimum / Maximum (mm.) : 8 and 27

● Precision (JIS) : Class 0

● Bearing Type : Closed (Double Shielded (ZZ))

● Load Direction : Radial Load

[Application]

It is used to support and guide rotating machine's components, such as shafts, wheels, pulleys ,etc

Economy Ball Bearing C3

- Ultra-low price meets industry vibration class Z1 requirements

- Available in various sizes with inner diameters within specified range.

- Double shielded design for enhanced dust resistance

- Precision class 0 for reliable performance

- Ideal for applications requiring thermal expansion accommodation

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Product of Ball Bearings Overview

・ It is made of industry standard Ball Bearings steel with high surface hardness and wear resistance.

・ The vibration class of the product is above Z1

Product of Ball Bearings Feature

・ In addition to the open type bearings, there are Ball Bearings with steel dust cover, bearings with contact rubber seal packing and bearings with non-contact rubber seal packing, or bearings with stop ring on the outer diameter of outer ring.

・ Ball bearings with dust cover or seal packing are sealed with proper amount of high-quality grease. Deep groove ball bearings generally adopt steel plate stamped cage, which has low friction torque and accuracy grade of 0.

Dimensional Ball Bearings Drawing

Example of Ball Bearings Use

Precautions for Using Ball Bearings

Please use the following special mounting tool for installation and removal