Timing Pulleys S3M

Caution

- This product [Timing Pulley] has scheduled to discontinue on 14042025. However, we will continue to sell until stock ran out.

- Download Free! >>Economy Series Catalog ver2023 (TH-EN)_Part05 CLICK here

Product Description

Timing Pulleys S3M

Timing Pulleys are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Belt Width Used (mm.) : 6, 10 and 15

● Applicable with Belt Type : S3M

● Number of Teeth Minimum/Maximum : 14 to 48

● Shaft Bore Diameter Minimum/Maximum (mm.) : 4 to 20

● Shaft Bore Specs. : Can select between Round Hole, Round Hole + Tap and New JIS keyway + Tap

● Material : Aluminum Alloy

● Surface treatment : Clear Anodized

[Application]

Timing pulleys are frequently utilized in systems that incorporate timing belts to regulate and govern the movement of the machinery.

Economy S3M Timing Pulley

- Wide variety of sizes from 14 to 48 teeth

- Made of durable and lightweight aluminum

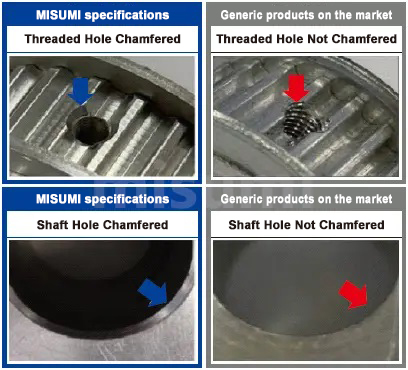

- Easy assembly with chamfered fixing screw holes

- Suitable for medium-precision reciprocating and conveyance systems

- Clear anodized surface for enhanced corrosion resistance

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

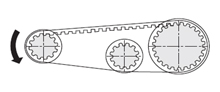

Driving and transmission are realized through the engagement between the teeth, timing idlers and timing belts.

| ■Standard Tooth Profile | ■Pulley Shape Shape K | Shape A | Shape B |

|  |  |  |

| The tooth groove size varies slightly with the number of teeth (Tooth pitch: 3.0mm) | |||

■Shalf Hole Specs. H Round Hole | P Round Hole+Tap | N New JIS Keyway+Tap | |

|  |  | |

For Shape A pulley, the tapped holes are set around 120° to avoid interference with the tooth top. For Shape A pulley, the tapped holes are set around 120° to avoid interference with the tooth top. The flange is riveted The flange is riveted |  Detailed Dimensions of Keyway Detailed Dimensions of Keyway The positions of keyway and teeth are not fixed. The positions of keyway and teeth are not fixed. |

Threaded Hole Size Table

(Shaft hole specifications: P·N·C)

| dH7 Shaft Hole ID | M (Coarse Thread) | Recommended Fixing Screw |

| 4~5 | M3 | M3×3 |

| 6~17 | M4 | M4×3 |

| 18~33 | M5 | M5×4 |

| 34~42 | M6 | M6×5 |

Material Material |  Surface Treatment Surface Treatment | |

| Pulley | Flange | |

| Aluminum Alloy | Aluminum Alloy | Clear Anodized |

| Part Number |  Pulley Shape |  Shaft Hole Specs .P Hole Dia. d | P.D. | O.D. | F | E | ||

Type Type |  Number of Teeth Number of Teeth |  Belt Type Belt Type | ||||||

| C-HTPA | 15 | S3M100 | A | 5 | 14.32 | 13.56 | 18 | 11 |

| 16 | 5 | 15.28 | 14.52 | 18 | 11 | |||

| 18 | 5·6 | 17.19 | 16.43 | 20 | 13 | |||

| 20 | 5·6 | 19.1 | 18.34 | 22 | 14 | |||

| S3M150 | 6 | |||||||

| 22 | S3M100 | 5·6·6.35·8 | 21.01 | 20.05 | 25 | 16 | ||

| S3M150 | 8 | |||||||

| 24 | S3M060 | 4·5·6·6.35·8·10 | 22.92 | 22.16 | 25 | 16 | ||

| S3M100 | 5·6·6.35·8·10 | |||||||

| S3M150 | 6·8 | |||||||

| 25 | S3M060 | 4·5·6·6.35·8·10 | 23.87 | 23.11 | 28 | 18 | ||

| S3M100 | 4·5·6·6.35· 8·10·11 | |||||||

| S3M150 | 8 | |||||||

| 26 | S3M060 | 5·6·6.35·8·10 | 24.83 | 24.07 | 28 | 18 | ||

| S3M100 | 5·6·6.35·8·10 | |||||||

| S3M150 | 8 | |||||||

| 28 | S3M060 | 5·6·6.35·8·10·12 | 26.74 | 25.98 | 30 | 20 | ||

| S3M100 | 5·6·6.35·8· 10·12·13 | |||||||

| S3M150 | 8 | |||||||

| 30 | S3M060 | 6·6.35·8·10· 12·14·15 | 28.65 | 27.89 | 32 | 23 | ||

| S3M100 | 6·6.35·8·10·12· 12.7·13·14·15 | |||||||

| S3M150 | 8·10·12·14 | |||||||

| 32 | S3M060 | 8·10·12·16 | 30.56 | 29.8 | 35 | 25 | ||

| S3M100 | 6·6.35·8·10·12·14 | |||||||

| S3M150 | 8 | |||||||

| 34 | S3M100 | 6·8·10·18 | 32.47 | 31.71 | 40 | 28 | ||

| S3M150 | 8 | |||||||

| 36 | S3M060 | 6·6.35·8·10·12 | 34.38 | 33.62 | 40 | 28 | ||

| S3M100 | 6·6.35·8·10 | |||||||

| S3M150 | 8·10·12 | |||||||

| 40 | S3M060 | 8·12 | 38.2 | 37.44 | 44 | 32 | ||

| S3M100 | 8·10·12·20 | |||||||

| S3M150 | 8·10 | |||||||

| 44 | S3M100 | 8·10·14·25 | 42.02 | 41.25 | 48 | 36 | ||

| 48 | S3M060 | 8·10 | 45.84 | 45.07 | 50 | 38 | ||

| S3M100 | 8·10·12 | |||||||

| 50 | S3M060 | 10 | 47.75 | 46.98 | 52 | 40 | ||

| S3M100 | 8·10·22 | |||||||

| 60 | 30 | 57.3 | 56.53 | 61 | 46 | |||

| 72 | 10·12.7·30 | 68.75 | 67.99 | 74 | 58 | |||

| Part Number |  Pulley Shape |  Shaft Hole Specs .N Hole Dia. d | P.D. | O.D. | F | E | ||

Type Type |  Number of Teeth Number of Teeth |  Belt Type Belt Type | ||||||

| C-HTPA | 25 | S3M060 | A | 8·10·NK10 | 23.87 | 23.11 | 28 | 18 |

| S3M100 | 8·10·11·NK10 | |||||||

| S3M150 | 8·10·11 | |||||||

| 26 | S3M060 | 8·10 | 24.83 | 24.07 | 28 | 18 | ||

| S3M100 | 8·10·11·NK10 | |||||||

| S3M150 | 8·10·NK10 | |||||||

| 28 | S3M060 | 8·10·12 | 26.74 | 25.98 | 30 | 20 | ||

| S3M100 | 8·10·11·12·13 | |||||||

| S3M150 | 8·10·12 | |||||||

| 30 | S3M060 | 8·10·12·14 | 28.65 | 27.89 | 32 | 23 | ||

| S3M100 | 8·10·11·12· 13·14·NK10 | |||||||

| S3M150 | 8·10·12·14·NK10 | |||||||

| 32 | S3M060 | 8·10·12·14·17 | 30.56 | 29.8 | 35 | 25 | ||

| S3M100 | 8·10·11·12·14· 15·16·17·NK10 | |||||||

| S3M150 | 8·10·12·14· 15·16·NK10 | |||||||

| 34 | S3M100 | 8·10·11·12·14·15 | 32.47 | 31.71 | 40 | 28 | ||

| S3M150 | 10·12·14·15 | |||||||

| 36 | S3M060 | 8·12 | 34.38 | 33.62 | 40 | 28 | ||

| S3M100 | 8·10·11·12·14· 15·17·NK10 | |||||||

| S3M150 | 10·12·13·14· 15·NK10 | |||||||

| 40 | S3M100 | 8·10·11·12· 14·15·20 | 38.2 | 37.44 | 44 | 32 | ||

| S3M150 | 10·11·12·14· 15·17·19·20 | |||||||

| 44 | S3M100 | 8·10·12·14· 15·NK10 | 42.02 | 41.25 | 48 | 36 | ||

| S3M150 | 12·14 | |||||||

| 48 | S3M060 | 15 | 45.84 | 45.07 | 50 | 38 | ||

| S3M100 | 8·10·14·15 | |||||||

| S3M150 | 10·12·19 | |||||||

| 50 | S3M100 | 8·10·14·20·25 | 47.75 | 46.98 | 52 | 40 | ||

| S3M150 | 14·15·29 | |||||||

| 60 | S3M060 | 8 | 57.3 | 56.53 | 61 | 46 | ||

| S3M100 | 8·12·14 | |||||||

| S3M150 | 10·12·19·22 | |||||||

| 72 | S3M100 | 20·25 | 68.75 | 67.99 | 74 | 58 | ||

| S3M150 | 12 | |||||||

Detailed specifications are available on the official website

Detailed specifications are available on the official website| Part Number |  Pulley Shape |  Shaft Hole Specs.H Hole Dia. d | P.D. | O.D. | F | E | ||

Type Type |  Number of Teeth Number of Teeth |  Belt Type Belt Type | ||||||

| C-HTPA | 14 | S3M060 | A | 5·6 | 13.37 | 12.61 | 16 | 10 |

| 15 | 5·6 | 14.32 | 13.56 | 18 | 11 | |||

| 16 | 5·7 | 15.28 | 14.52 | 18 | 11 | |||

| S3M100 | 6·7 | |||||||

| 18 | S3M060 | 5·6·8 | 17.19 | 16.43 | 20 | 13 | ||

| S3M100 | 6.35·8 | |||||||

| 19 | 8 | 18.14 | 17.28 | 22 | 14 | |||

| 20 | S3M060 | 5·6·8·9 | 19.1 | 18.34 | 22 | 14 | ||

| S3M100 | 8 | |||||||

| 22 | S3M060 | 5·6·8·10 | 21.01 | 20.25 | 25 | 16 | ||

| 24 | 10 | 22.92 | 22.16 | 25 | 16 | |||

| S3M100 | 4·8 | |||||||

| 26 | S3M060 | 5 | 24.83 | 24.07 | 28 | 18 | ||

| S3M100 | 10 | |||||||

| 28 | S3M060 | 8 | 26.74 | 25.98 | 30 | 20 | ||

| S3M100 | 13 | |||||||

| 30 | 10·12·18 | 28.65 | 27.89 | 32 | 23 | |||

| 32 | 6.35·8 | 30.56 | 29.8 | 35 | 25 | |||

| 60 | 22·28 | 57.3 | 56.53 | 61 | 46 | |||

| Part Number |  带轮 形状 |  Shaft Hole Specs.H Hole Dia. d | P.D. | O.D. | D | F | E | ||

Type Type |  Number of Teeth Number of Teeth |  Belt Type Belt Type | |||||||

| C-HTPA | 24 | S3M100 | B | 6·6.35 | 22.92 | 22.16 | 14 | 25 | 16 |

| 28 | 6.35·8 | 26.74 | 25.98 | 18 | 30 | 20 | |||

| 32 | 14 | 30.56 | 29.8 | 20 | 35 | 25 | |||

| 48 | S3M060 | 20 | 45.84 | 45.07 | 34 | 50 | 38 | ||

| Part Number |  Pulley Shape |  Shaft Hole Specs.P Hole Dia. d | P.D. | O.D. | D | F | E | ||

Type Type |  Number of Teeth Number of Teeth |  Belt Type Belt Type | |||||||

| C-HTPA | 24 | S3M060 | B | 5·6·6.35·8 | 22.92 | 22.16 | 14 | 25 | 16 |

| S3M100 | 5·6·6.35·8 | ||||||||

| S3M150 | 8 | ||||||||

| 25 | S3M060 | 5·6·8·10 | 23.87 | 23.11 | 16 | 28 | 18 | ||

| S3M100 | 5·6·6.35·8·10 | ||||||||

| 26 | S3M060 | 8·10 | 24.83 | 24.07 | 16 | 28 | 18 | ||

| S3M100 | 6.35·8 | ||||||||

| 28 | S3M060 | 5·6.35·8·10 | 26.74 | 25.98 | 18 | 30 | 20 | ||

| S3M100 | 5·6·6.35·8 | ||||||||

| 30 | S3M060 | 8·10 | 28.65 | 27.89 | 20 | 32 | 23 | ||

| S3M100 | 6.35·8·10·12 | ||||||||

| S3M150 | 8·12 | ||||||||

| 32 | S3M060 | 8·10 | 30.56 | 29.8 | 20 | 35 | 25 | ||

| S3M100 | 6.35·8 | ||||||||

| S3M150 | 6.35·8 | ||||||||

| 34 | S3M060 | 8·14 | 32.47 | 31.71 | 26 | 40 | 28 | ||

| S3M100 | 8·10·12·14 | ||||||||

| 36 | S3M060 | 13 | 34.38 | 33.62 | 26 | 40 | 28 | ||

| S3M100 | 6.35·8 | ||||||||

| 40 | 8·10·11·12· 14·18·20 | 38.2 | 37.44 | 30 | 44 | 32 | |||

| 48 | S3M060 | 8 | 45.84 | 45.07 | 34 | 50 | 38 | ||

| 50 | S3M100 | 8 | 47.75 | 46.98 | 34 | 52 | 40 | ||

| 72 | 15 | 68.75 | 67.99 | 50 | 74 | 58 | |||

| Part Number |  Pulley Shape |  Shaft Hole Specs.H Hole Dia. d | P.D. | O.D. | D | F | E | ||

Type Type |  Number of Teeth Number of Teeth |  Belt Type Belt Type | |||||||

| C-HTPA | 16 | S3M060 | K | 5 | 15.28 | 14.52 | 18 | 18 | 11 |

| 18 | S3M150 | 8 | 17 | 16.43 | 20 | 20 | 13 | ||

| 20 | S3M060 | 5·8 | 19.1 | 18.34 | 22 | 22 | 14 | ||

| 22 | S3M100 | 5 | 21.01 | 20.25 | 25 | 25 | 16 | ||

| Part Number |  Pulley Shape |  Shaft Hole Specs.P Hole Dia. d | P.D. | O.D. | D | F | E | ||

Type Type |  Number of Teeth Number of Teeth |  Belt Type Belt Type | |||||||

| C-HTPA | 14 | S3M060 | K | 4·5·6 | 13.37 | 12.61 | 16 | 16 | 10 |

| S3M100 | 4·5·6 | ||||||||

| 15 | S3M060 | 5·6 | 14.32 | 13.56 | 18 | 18 | 11 | ||

| S3M100 | 5·6 | ||||||||

| 16 | S3M060 | 4·5·6·6.35 | 15.28 | 14.52 | 18 | 18 | 11 | ||

| S3M100 | 5·6·7·6.35 | ||||||||

| S3M150 | 6.35 | ||||||||

| 18 | S3M060 | 5·6·6.35·8 | 17.19 | 16.43 | 20 | 20 | 13 | ||

| S3M100 | 5·6·6.35·8 | ||||||||

| S3M150 | 8 | ||||||||

| 20 | S3M060 | 4·5·6·6.35·8 | 19.1 | 18.34 | 22 | 22 | 14 | ||

| S3M100 | 5·6·6.35·8 | ||||||||

| S3M150 | 8 | ||||||||

| 22 | S3M060 | 5·6·6.35·8 | 21.01 | 20.25 | 25 | 25 | 16 | ||

| S3M100 | 5·6·6.35·8·10 | ||||||||

| S3M150 | 10 | ||||||||

Detailed specifications are available on the official website

Detailed specifications are available on the official website| Part Number |  Pulley Shape |  Shaft Hole Specs.N Hole Dia. d | P.D. | O.D. | D | F | E | ||

Type Type |  Number of Teeth Number of Teeth |  Belt Type Belt Type | |||||||

| C-HTPA | 25 | S3M060 | B | 8 | 23.87 | 23.11 | 16 | 28 | 18 |

| S3M100 | 8 | ||||||||

| S3M150 | 8 | ||||||||

| 26 | S3M060 | 8 | 24.83 | 24.07 | 16 | 28 | 18 | ||

| S3M100 | 8 | ||||||||

| S3M150 | 8 | ||||||||

| 28 | S3M100 | 8 | 26.74 | 25.98 | 18 | 30 | 20 | ||

| 30 | S3M060 | 8 | 28.65 | 27.89 | 20 | 32 | 23 | ||

| S3M100 | 8·10·11·NK10 | ||||||||

| S3M150 | 8 | ||||||||

| 32 | S3M060 | 8 | 30.56 | 29.8 | 20 | 35 | 25 | ||

| S3M100 | 8·10 | ||||||||

| S3M150 | 8 | ||||||||

| 34 | S3M100 | 8·10·12·13·14 | 32.47 | 31.71 | 26 | 40 | 28 | ||

| S3M150 | 14 | ||||||||

| 36 | S3M060 | 10·14 | 34.38 | 33.62 | 26 | 40 | 28 | ||

| S3M100 | 14 | ||||||||

| 40 | S3M100 | 8·10·14·15 | 38.2 | 37.44 | 30 | 44 | 32 | ||

| S3M150 | 14 | ||||||||

| 44 | S3M100 | 8 | 42.02 | 41.25 | 32 | 48 | 36 | ||

| 48 | S3M150 | 16 | 45.84 | 45.07 | 34 | 50 | 38 | ||

| 50 | S3M060 | 8 | 47.75 | 46.98 | 34 | 52 | 40 | ||

| 60 | S3M100 | 8 | 57.3 | 56.53 | 39 | 61 | 46 | ||

Please visit MISUMI website for details of the models available for sale.

Please visit MISUMI website for details of the models available for sale.| New Products | Existing Products | |

| Example of use |  |  |

| Precautions | Generally used in reciprocating and conveyance mechanisms that do not have high requirements on positioning accuracy. | Generally used in mechanisms that frequently rotate forwardly and reversely and have requirements on positioning accuracy and backlash. |

| Repetitive positioning accuracy (reference value) | Medium precision (±0.1) | High precision (±0.05) |

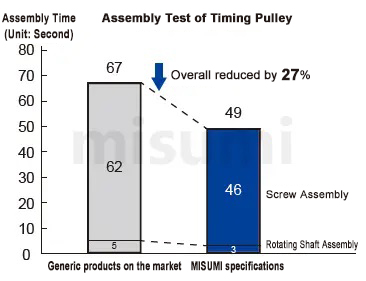

·MISUMI Economy series timing pulley is chamfered at the shaft hole and tapped hole for easy installation, reducing assembly time by 27% compared to the timing pulley not chamfered

※Generic products on the market are similar products randomly purchased by our company from online or offline markets

※The test result are obtained through testing by our company, which are for reference only

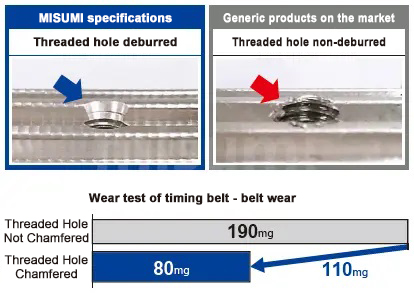

·MISUMI Economy series timing pulley, with deburring treatment at the threaded hole, is not easy to wear the timing belt, and the price is cheap while increasing the lifetime of the timing belt.

| Belt condition after the test of timing belt pulley without chamfer on the threaded hole: there are obvious wear marks left by the pulley tooth threaded hole on the belt tooth surface.  | 【Test Condition】 Belt Specification: S5M Belt Width: 150mm Number of teeth of drive side pulley: 20 Number of teeth of driven side pulley: 60 Rotational speed: 3000rpm Tension (N): 160N Test time: 24H |

Timing PulleyTiming Pulley For hole specifications P (round hole + threaded hole) or N (round hole + keyway hole), the fixing screws are not included, and you may purchase them from MISUMI according to the recommended fixing screw models.

Timing PulleyTiming Pulley For hole specifications P (round hole + threaded hole) or N (round hole + keyway hole), the fixing screws are not included, and you may purchase them from MISUMI according to the recommended fixing screw models. Timing PulleyThere may be no surface treatment in the shaft hole.

Timing PulleyThere may be no surface treatment in the shaft hole. Timing PulleyThe positions of keyway and tooth are not fixed.

Timing PulleyThe positions of keyway and tooth are not fixed.| Usage Method Example Drawing | Usage Method of Timing Wheel and Timing Belt |

| ①Driving The driven wheel is driven by the driving wheel for transmission |

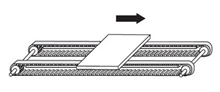

| ②Linear driving Reciprocating motion is carried out through the self-end timing toothed belt. |

| Usage Method Example Drawing | Usage Method of Timing Wheel and Timing Belt |

| ③Conveyance Plates are conveyed by two timing toothed belts |

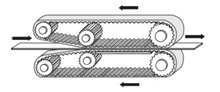

| ④Traction transmission Workpieces are clamped and transmitted by the belt |

Timing Pulleys S Type, suitable for MISUMI Standard Timing Belts and Economy Series Timing Belts.

Timing Pulleys S Type, suitable for MISUMI Standard Timing Belts and Economy Series Timing Belts.

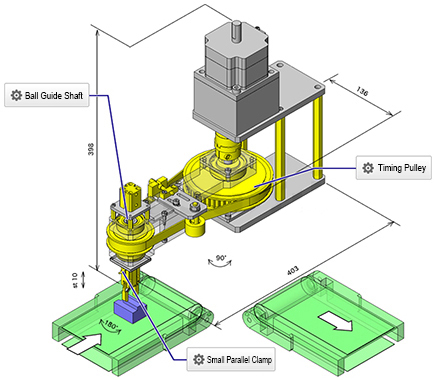

Workpiece reversal transfer mechanism

■ Mechanism function

Rotates the workpiece on the conveyor belt by 90 degrees and transfers it to the next process.

At this time, the clamping mechanism rotates 180 degrees and does not change the direction of the workpiece relative to the conveying direction at the same time during transfer.

■Role of the Timing Pulley

The transmission of the timing pulley and the timing belt changes the placement direction of the workpiece while transferring the workpiece. (Applicable to S specification and GT specification timing pulleys)

| Semiconductor | Automotive | Smart Phones | ||

|  |  | ||

| Medical | Electronic & Electrical | Robotics | ||

|  |  |

| Flat-belt idlers, Width (T), 6 to 32 mm | Flat Belts For General Use | High Torque Timing Pulleys S2M Type | ||

|  |  | ||

| Representative model: HBG15-6 | Representative model: HBLT350-4.23 | Representative model: HTPA48S2M040-B-N10 | ||

| Advantages: short delivery time, multiple types | Advantage: custom size | Advantages: short delivery time, multiple types |

①Data on the selection of timing pulleys and timing toothed belts, tensioning force, etc. (drive).

②Data on the selection of timing pulleys and timing toothed belts, tensioning force, etc. (transmission & conveyance).

③Main causes and countermeasures for the damage, breakage, abnormal noise of timing toothed belts.

④Reference data on the replacement time of timing toothed belts.

⑤Data on dimensional tolerance of timing pulleys and timing idlers.