Press Fit Ball Plungers

Caution

- Download Free! >>Economy Series Catalog ver2023 (TH-EN)_Part10 CLICK here

Product Description

- Economy series Press Fit Ball Plungers

- Part number are series: C-PFSSN, C-PFSSR, C-PFPSN and C-PFPPN.

- Press Fit Ball Plungers type: Light Load and Heavy Load.

- Main Body Material: SUS303 and POM.

- Ball Material: SUS440C and POM.

- Ball Hardness: 50HRC.

- Spring Material: Stainless Steel SUS304.

- Press Fit Plungers Mounting Method: Press Fit.

- Coarse Thread Size (M): 3, 4, 5, 6, 8 and 10.

- Package Quantity: 10 and 20 PCS (Please check before order)

- No threaded hole required Short and light Easy to install.

Economy Press Fit Ball Plunger (Stainless/POM)

- Wide Range Of Specifications For Different Needs

- High-Quality Stainless Steel Or Polyacetal Material

- Suitable For Equipment With High Surface Requirements

- Simple Installation With Press Fit Design

- Cost-Effective And Durable Solution

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Product Overview of Ball Plungers

·Ball Plungers, also known as ball point set screws, ball screws, positioning balls, touch balls, steel ball tightening spring screws, etc., can be used for temporary positioning and index adjustment of workpieces, relying on the spring to push out the front ball through a fixed stroke.

·The plunger body and ball are made of either stainless steel or polyacetal, available in four combinations.

·Note that the appearance and dimensional tolerances of the stainless steel body and the polyacetal body are slightly different. See the Specification Table for details.

Product Feature of Ball Plungers

·With no painting or coloring, they are suitable for more equipment with higher surface requirements.

·The Ball Plungers has a simple structure: the front ball is pushed out through a fixed stroke by the internal spring and it can be released by pressing in the ball against the elastic force.

·Flexible installation: Suitable for linear motion and rotary motion mechanisms with positioning requirements, the Ball Plungers can be installed using general threads, which facilitates assembly and disassembly.

·Suitable for fixture indexing, positioning, stop limit and other occasions.

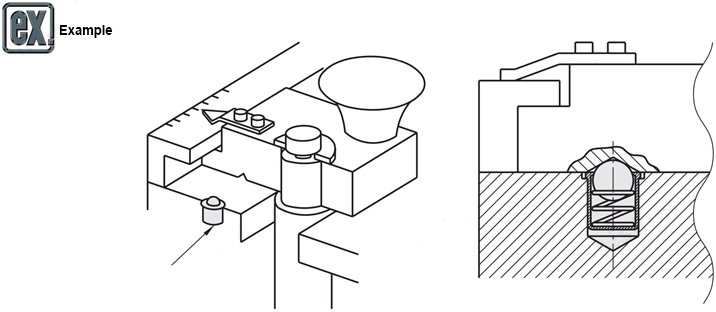

Example Use of Ball Plungers

Usage Method of Ball Plungers

Ball Plungers, Apply adhesive before use to prevent it from falling off.

Precautions of Ball Plungers

·Ball Plungers, No anti-loosening treatment.

Related products of Ball Plungers

| (Economy series) Stainless Steel Standard Ball Plungers | (Economy series) Stainless Steel Long Ball Plungers | (Economy series) White Zinc-Plated Ball Plungers |

|  |  |

| Type | Body | Ball | Spring | ||

Material Material |  Material Material |  Hardness Hardness |  Material Material | ||

| Light Load | C-PFSSN | SUS303 | SUS440C | 50HRC | SUS304 |

| Heavy Load | C-PFSSR | ||||

| Light Load | C-PFPSN | POM | |||

| C-PFPPN | POM | - | |||

Product Drawings

| Part Number | D1 | L | S | d | c | Light Load (N) | Heavy Load (N) | |||||

| Type | D | Package Quantity | SUS303 Body | POM Body | min. | max. | min. | max. | ||||

| C-PFSSN C-PFSSR C-PFPSN C-PFPPN | 3 | 20P | 3.6 | 4 | 0.8 | 0.6 | 2.38 | 0.8 | 2 | 4 | - | - |

| 4 | 4.6 | 5 | 1.1 | 0.9 | 3 | 0.8 | 3 | 5 | 3 | 10 | ||

| 5 | 5.6 | 6 | 1.4 | 1.2 | 4 | 1 | 4 | 7 | 5 | 10 | ||

| 6 | 10P | 6.5 | 7 | 1.8 | 1.6 | 5 | 1 | 5 | 9 | 5 | 12 | |

| 8 | 8.5 | 9 | 2 | 1.8 | 6 | 1.2 | 7 | 11 | 6 | 15 | ||

| 10 | 11 | 13 | 2.8 | 2.6 | 8 | 1.5 | 9 | 15 | 6 | 20 | ||