Ball Plungers Stainless Steel, White Zinc Plated

Caution

- Download Free! >>Economy Series Catalog ver2023 (TH-EN)_Part10 CLICK here

Product Description

- Economy series Ball Plungers Stainless Steel, White Zinc Plated.

- The series including of C-BPU (Light Load) and C-BPM (Heavy Load).

- Main Body Material: S45C White Zinc Plating is cost effective option.

- Ball Material: Stainless Steel SUS440C

- Ball Hardness: 52HRC.

- Spring Material: Stainless Steel SUS304.

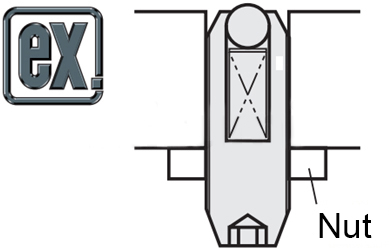

- Mounting Method: Screw (Hex).

- Coarse Thread Size (M): 4, 5, 6 and 8.

- Ball Plungers suitable for medical, electronic, and other equipment with high surface requirements.

- For MISUMI Economy series ball plungers without painting and coloring.

Economy White Zinc Plated Ball Plunger (M4-M8 Thread)

- Zinc Plating For Enhanced Corrosion Resistance

- Suitable For Low And Medium Precision Equipment

- High Load Capacity With Stainless Steel Ball

- Easy Installation With Hex Screws

- Flexible And Cost-Effective Solution

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Product Overview of Ball Plungers

·Ball Plungers, also known as ball point set screws, ball screws, positioning balls, touch balls, steel ball tightening spring screws, etc., can be used for temporary positioning and index adjustment of workpieces, relying on the spring to push out the front ball through a fixed stroke.

Product Feature of Ball Plungers

·With no painting or coloring, they are suitable for more equipment with higher surface requirements.

·As there is no wrench slot on the tip, please use the Ball Plungers with an Allen wrench.

·The Ball Plungers has a simple structure: the front ball is pushed out through a fixed stroke by the internal spring and it can be released by pressing in the ball against the elastic force.

·Flexible installation: Suitable for linear motion and rotary motion mechanisms with positioning requirements, the plunger can be installed using general threads, which facilitates assembly and disassembly.

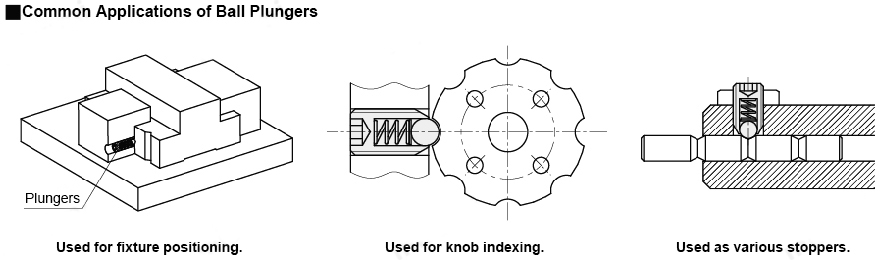

·Suitable for fixture indexing, positioning, stop limit and other occasions.

·The stroke can be fine-tuned by screwing-in depth of the screw.

Example Use of Ball Plungers

Usage Method of Ball Plungers

Precautions of Ball Plungers

·The values of stroke (S), slot size (B) and load are for reference only and not guaranteed.

·Ball Plungers, No anti-loosening treatment.

Related products of Ball Plungers

| (Economy series) Stainless Steel Standard Ball Plungers | (Economy series) Stainless Steel Long Ball Plungers | (Economy series) Black Zinc-Plated Ball Plungers |

|  |  |

| Type | Body | Ball | Spring | |||

Material Material |  Surface Treatment Surface Treatment |  Material Material |  Hardness Hardness |  Material Material | ||

| Light Load | C-BPU | S45C | Galvanized | SUS440C | 52HRC | SUS304 |

| Heavy Load | C-BPM | |||||

Product Drawings

| Part Number | d | S | L | B | Light Load | Heavy Load | ||||

| Type | M (Coarse Thread) | Package Quantity | Load (N) | Load (N) | ||||||

| min. | max. | min. | max. | |||||||

| C-BPU C-BPM | 4 | 20P | 2.38 | 0.8 | 10 | 2 | 2 | 5 | 3 | 20 |

| 5 | 3 | 1 | 12 | 2.5 | 3 | 10 | 4 | 20 | ||

| 6 | 10P | 3.5 | 1.2 | 3 | 5 | 15 | 5 | 30 | ||

| 8 | 5 | 1.6 | 16 | 4 | 7 | 20 | 6 | 50 | ||