Neodymium Magnets Flat Shape for Countersunk

Caution

- Download Free! >>Economy Series Catalog ver2023 (TH-EN)_Part21 CLICK here

Product Description

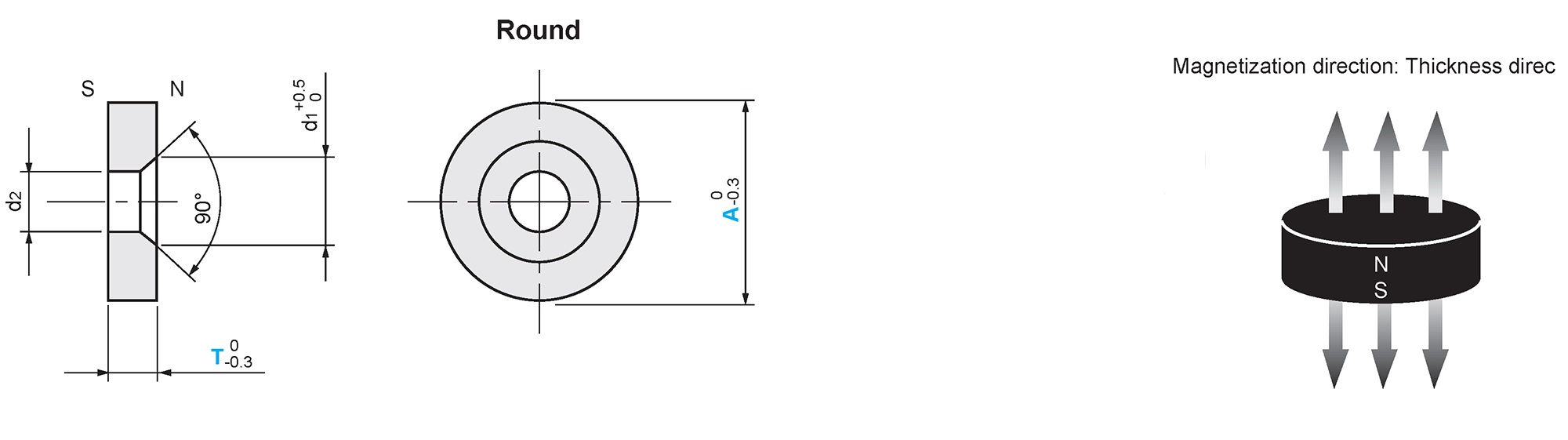

Neodymium Magnets Flat Shape for Countersunk is a type of magnet that has a countersunk hole in the center.They offer a wide variety of sizes to choose from.

[Feature]

● Shape and size :

- Round /Outer Diameter Minimum/Maximum (mm.) : 8 and 20

- Square /Width Minimum/Maximum (mm.) : 8 and 20

● The countersunk hole allows for the magnet to be easily mounted onto a surface using a screw

● Material and Heat Resistant Temperature (°C)

-Neodymium Magnet / 80°C

-Heat-resistant Neodymium Magnets 150°

[Application]

These Neodymium magnets are commonly used in various applications such as tool holders, magnetic clamping blocks

At present, domestic and foreign customers often use Magnets - Round units at the design level in automated machinery and equipment, which are relatively versatile and can be changed flexibly according to customer needs.

■ MISUMI economy series Magnets - Round with holders come in a variety of cases, are easier to install, and more than twice as robust as the adhered units of single magnets.

• 98 specifications in 11 series

■Surface finish may vary slightly between batches due to coating differences; this does not affect performance.

■Flat-head bolt-type magnets have a thinner inner wall and are more fragile, install with a sliding motion to avoid damage.

■Product upgrade in progress: newer versions include a stainless steel flat-head screw. Both old and new versions meet quality standards.

| Part Number |  Thickness T Thickness T | d1 | d2 | Accessories (To be equipped by yourself) | Attraction Force N{kgf} | ||

Type Type |  O.D. A O.D. A | Round | Round Heat-resistant | ||||

| C-NHXCC C-NHXCC-S (Round Neodymium Magnet) C-NHXCCH C-NHXCCH-S (Round Heat-resistant Neodymium Magnet) | 8 | 2 | 5.5 | 3 | M2.5-6 | 7.8{0.8} | 7.8{0.8} |

| 3 | 10.8{1.1} | 10.8{1.1} | |||||

| 4 | M2.5-8 | 12.5{1.3} | - | ||||

| 10 | 3 | 6.5 | 3.5 | M3-8 | 14.7{1.5} | 14.7{1.5} | |

| 4 | 18.6{1.9} | 18.6{1.9} | |||||

| 5 | M3-10 | 21.5{2.2} | - | ||||

| 12 | 3 | M3-8 | 18.6{1.9} | ||||

| 4.5 | 23.5{2.4} | 23.5{2.4} | |||||

| 15 | 3 | 9 | 4.8 | M4-10 | - | ||

| 5 | 41.1{4.2} | 41.1{4.2} | |||||

| 20 | 4 | 11 | 5.8 | M5-12 | 49{5.0} | - | |

| 5.5 | 54.8{5.6} | 54.8{5.6} | |||||

| 25 | 4 | 13 | 7 | M6-15 | 58.8{6.0} | - | |

| 6 | 78.4{8.0} | 78.4{8.0} | |||||

Attraction and surface flux density refer to the values of a single magnet (reference value).

Attraction and surface flux density refer to the values of a single magnet (reference value). Please visit MISUMI website for details of the models available for sale.

Please visit MISUMI website for details of the models available for sale.| Part Number |  Thickness T Thickness T | Surface flux density Gauss [G] | ||

Type Type |  O.D. A O.D. A | Round | Round Heat-resistant | |

| C-NHXCC C-NHXCC-S (Round Neodymium Magnet) C-NHXCCH C-NHXCCH-S (Round Heat-resistant Neodymium Magnet) | 8 | 2 | 2700~2900 | 2700~2900 |

| 3 | 2900~3100 | 2900~3100 | ||

| 4 | 3000~3300 | |||

| 10 | 3 | 3400~3700 | 3400~3700 | |

| 4 | 3900~4200 | 3900~4200 | ||

| 5 | 3900~4200 | - | ||

| 12 | 3 | 3500~3700 | - | |

| 4.5 | 4100~4300 | 4100~4300 | ||

| 15 | 3 | 3400~3700 | - | |

| 5 | 4000~4300 | 4000~4300 | ||

| 20 | 4 | 3200~3500 | - | |

| 5.5 | 3900~4200 | 3900~4200 | ||

| 25 | 4 | 3200~3600 | - | |

| 6 | 3600~4000 | 3600~4000 | ||

| Neodymium Magnets - Round | Neodymium magnets are the most powerful magnets of all, and are ideal for reducing size and increasing the performance of devices. The disadvantage is that it is very easy to rust. Cobalt magnet and it are known as rare earth magnets. |

| Cobalt Magnets - Round | It is officially known as samarium cobalt magnet, with a strong magnetic force second only to neodymium magnet. Its advantage is being not prone to rusting and resistant to high temperature. But it has poor mechanical strength and is easy to be broken, so be careful when using. |

| Ferrite Magnets - Round | Ferrite magnets have a weak magnetic force but relatively high retentivity, and magnetism is not easy to decay. It has poor mechanical strength and is easy to be broken, so be careful when using. |

| Al-Fe-Ni-Co Magnets - Round | It has both the advantage of high temperature resistance and excellent mechanical strength. The disadvantage is that magnetism is very easy to attenuate. |

■ MISUMI Economy series Rubber Coated Magnets - Round

・With a rubber protective layer that can effectively prevent scratches, reducing them by 99%, the magnet is suitable for adsorption on surface sprayed workpieces.

※Generic products on the market are similar products randomly purchased by our company from online or offline markets.

※The test data are obtained through testing by our company, which are for reference only.

■ As the Magnets - Round body is very hard and brittle, it is highly susceptible to being knocked and shattered when fetched and mounted by the customer.

※Generic products on the market are similar products randomly purchased by our company from online or offline markets.

※The test data are obtained through testing by our company, which are for reference only.

All Magnets - Round materials are very fragile, no alteration is available.

· Magnets - Round may be damaged if they are subjected to strong impacts. Be careful during use.

· The magnetic field generated by Magnets - Round may cause adverse effects on the following items.

Electronic devices such as cell phones, computers, clocks and watches,

and electronic medical devices such as pacemakers.

·The magnetic force may deteriorate when used at above the maximum operating temperature.

· Strong impact or alteration on Magnets - Round may cause magnetic force losses.

· To prevent direct impacts on Magnets - Round, maintain a clearance of 0.1 ~ 0.3mm or more.

The adsorption force of powerful neodymium magnets is about 30% higher than that of standard neodymium magnets. When taken out of the packaging bag, if there aremagnetic objects nearby, it may jump out and be sucked, causing the product to crack. Please be careful when using.

The adsorption force of powerful neodymium magnets is about 30% higher than that of standard neodymium magnets. When taken out of the packaging bag, if there aremagnetic objects nearby, it may jump out and be sucked, causing the product to crack. Please be careful when using.Load {kgf}=Load N×0.101972

● Don't apply alterations on Magnets - Round as they are fragile.

● Magnets - Round may be damaged by strong impacts applied directly to the magnet surface.

● Magnets - Round with holders have 0.1 to 0.3mm steps to protect the magnet surface from impacts.

There are 0.1~0.3mm steps.

● The magnet and holder are connected by adhesive.

“Attraction Force" indicates the power of lifting the mating material SS400 (polished surface of 10mm thick plate).