Jaw Couplings Clamping Type

Caution

- [Products scheduled to be discontinued]

This products is scheduled to be discontinued. Orders will be accepted until December 28, 2021.

The recommended alternative is the coupling jaw type clamping type (CPJC).

Please check the difference in specifications on the MISUMI-VONA product page. - Download Free! >> Misumi Economy_Series(THA)_Index04_Stepper_Motor_Coupling CLICK here

Product Description

This is an economy item, The price is cheaper than the MISUMI standard product.

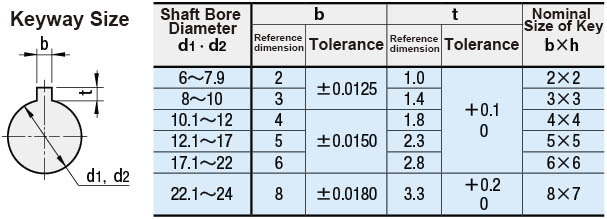

[Compatible with keyway holes] Spacers are pressed into the hub for excellent transmission performance. Jaw coupling that can absorb vibration with a polyurethane spacer.

Economy Jaw Coupling

- Flexible polyurethane spacer for shock absorption

- High torque capacity for demanding applications

- Lightweight and low moment of inertia

- Easy assembly and disassembly with clamping type

- Durable and long-lasting design

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Coupling Product Overview

The claw Coupling, also known as the plum Coupling, is composed of two Coupling metal claw discs and an elastomer resin adjusting ring.The resin adjusting ring can alleviate the inertia load impact when starting and stopping. Easy to disassemble and assemble.

Applicable motor types: recommended for stepping motors and universal motors.

Coupling Product Feature

Simple structure, no lubrication, convenient repair, easy inspection, maintenance free, and continuous long-term operation.

Urethane elastic parts are wear-resistant and oil-resistant, have large carrying capacity, long service life, and are safe and reliable.

They have excellent damping, cushioning and electrical insulation properties. They have great axial, radial, and angular compensation capabilities.

With simple structure, small radial dimension, light weight, and small moment of inertia, they are suitable for medium and high speed applications.

Dimensional Coupling Drawing

| Part Number |  Adjusting ring Adjusting ring(Color selection) |  d1, d1,  d2 selection (But d1≤d2) d2 selection (But d1≤d2) | L | ℓ | B | C | F | G | Fastening Bolt | ||||||||||||

Type Type |  D D | M | Tightening torque (N·m) | ||||||||||||||||||

| GCJC | 14 | BL(Blue) WH(White) RD(Red) | 4 | 5 | 22 | 7 | 6 | 1 | 3.5 | 4 | M2 | 0.5 | |||||||||

| 20 | 5 | 6 | 6.35 | 7 | 8 | 30 | 10 | 8 | 5 | 6.5 | M2.5 | 1 | |||||||||

| 30 | 7 | 8 | 10 | 12 | 35 | 11 | 10 | 1.5 | 5.5 | 10 | M4 | 2.5 | |||||||||

| 40 | 10 | 12 | 14 | 15 | 16 | 66 | 25 | 12 | 2 | 8.5 | 14 | M5 | 4 | ||||||||

| Part Number |  Adjusting ring Adjusting ring(Color selection) |  d1, d1,  d2 selection (But d1≤d2) d2 selection (But d1≤d2) | L | ℓ | B | C | F | G | Fastening Bolt | ||||||

Type Type |  D D | M | Tightening torque (N·m) | ||||||||||||

| GCJCLK GCJCRK GCJCWK | 30 | BL(Blue) WH(White) RD(Red) | 10 | 12 | 35 | 11 | 10 | 1.5 | 5.5 | 10 | M4 | 2.5 | |||

| 40 | 10 | 12 | 14 | 15 | 16 | 66 | 25 | 12 | 2 | 8.5 | 14 | M5 | 4 | ||

| Parts |  Material Material |  Surface Treatment Surface Treatment |  Accessories Accessories |

| Hub | Aluminum | Alumite Treatment | Hexagon socket head bolt |

| Spacer | Urethane | - |

Coupling Specifications Overview

| Selection | Color | Hardness Shore A |

| BL | Blue | 80 |

| WH | White | 92 |

| RD | Red | 98 |

Coupling Precautions

1. The Coupling allows axis deviation, and transmits rotation angle and torque, but when the axis deviation exceeds the allowable value, vibration will occur or the service life will be drastically reduced.

Be sure to make calibration and adjustment.

2. Axis deviation includes lateral misalignment (parallel error of two axes), angular misalignment (angular error of two axes) and axial amplitude (axial movement of shaft).

Please calibrate and adjust the shaft to ensure that the axis deviation is below the allowable value recorded in the dimension and performance table of each product.

3. The allowable value of axis deviation recorded in the dimension and performance table refers to the situation when either lateral misalignment, angular misalignment or axial amplitude occurs alone. When more than two axis deviations occur at the same time, the corresponding allowable values are halved respectively.

4. Axis deviation not only occurs when assembling to the device, but also is caused by vibration, thermal expansion and bearing wear in operation. Therefore, it is recommended to set the axis deviation below 1/3 of the allowable value.

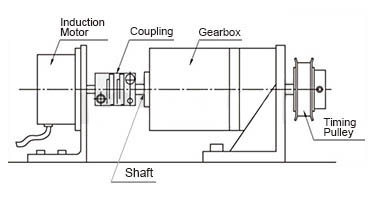

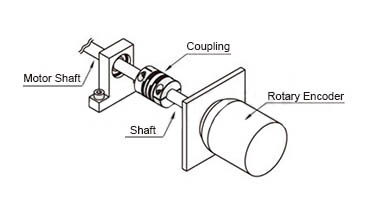

Example of Use Coupling

Coupling Usage Method

STEP1 Insert the Coupling

Confirm that the clamping bolt has been unscrewed, and then remove the dust, foreign matter and oil from the shaft and Coupling bore.

Then, when inserting the Coupling into the shaft, please be careful not to put the disc under excessive stress such as compression or tension.

STEP2 Use fixture to adjust

Please use fixture to adjust and fix the concentricity of the left and right hubs of the Coupling with high accuracy.

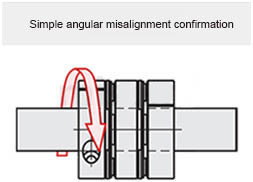

STEP3 Simple lateral misalignment and angular misalignment confirmation

Under the condition of unscrewed bolts, make the Coupling slide axially and confirm its smooth movement.

Then, rotate the Coupling to make sure it moves smoothly.

Lateral misalignment is not allowed for single disc type Coupling, so carry out positioning securely.

STEP4 Installation

Please adjust the shaft insertion amount according to the dimension ℓ in the product catalog, and use a torque wrench to tighten with the specified torque.

* If the specified torque cannot be reached once, please cross fasten the left and right clamps twice or three times.

Coupling Related Products

| (Economy series) GTR plum-shaped Coupling Clamping bolt fixing type/Clamping bolt with keyway type | Coupling Plum-shaped clamping screw fixing type JAAC buffer part material is blind hole (corresponding to LK8-C) | Plum-shaped clamping screw fixing type SJCM |

|  |  |