Oldham Couplings Clamping Type

Caution

- Download Free! >> Misumi Economy_Series(THA)_Index04_Stepper_Motor_Coupling CLICK here

Product Description

· GCOC/ GCOCRK/ GCOCWK Model Oldham Couplings Clamping Type.

· Couplings consisting of 2 hubs and 1 spacer disc.

· 2 hubs materials are aluminum alloy and surface treatment with alumite treatment.

· Spacer disc material is Polyacetal.

· Shaft Fastening Method: Lock bolt clamp screw type.

· Lock bolt clamp screw material: steel SCM435 surface treatment with Ferro ferric Oxide Protective Film.

· Oldham Coupling size: 16 to 32.

· Allowable Angular misalignment 3 degree.

· Operating Temperature Range: -20 to 80 °C

· Maximum Rotational Speed Range: 4001 ~ 10000 (r/min).

Economy Al/POM Oldham Coupling

- High torque capacity ensures reliable performance for demanding applications

- Allows for significant angular misalignment up to specified degree for versatile use.

- Made from durable aluminum and polyacetal for long-lasting operation

- Easy clamping type installation for quick and secure setup

- Operates efficiently at high rotational speeds

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Product Overview

■ Summary couplingFeatures: The quality and performance are the same as those of previous products, thus realizing low-cost supply. It can replace CPOC and CPO.

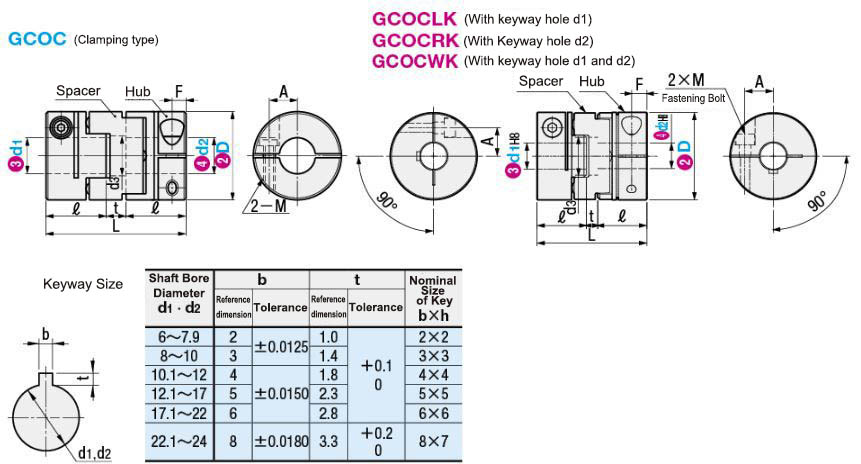

Dimensional Drawing

| Type |  Material Material |  Surface Treatment Surface Treatment |  Accessories Accessories | ||||||

| Standard Hole | d1(One side) | d2(One side) | d1, d2(Both sides) | Body | Spacer | Lock bolt clamp screw | Body | Lock screw clamp screw | |

| GCOC | GCOCLK | GCOCRK | GCOCWK | Aluminum | Polyacetal | SCM435 | Alumite Treatment | Ferroferric Oxide Protective Film | Lock Bolt |

| GCO | GCOLK | GCORK | GCOWK | Clamp Screw | |||||

Specification Table

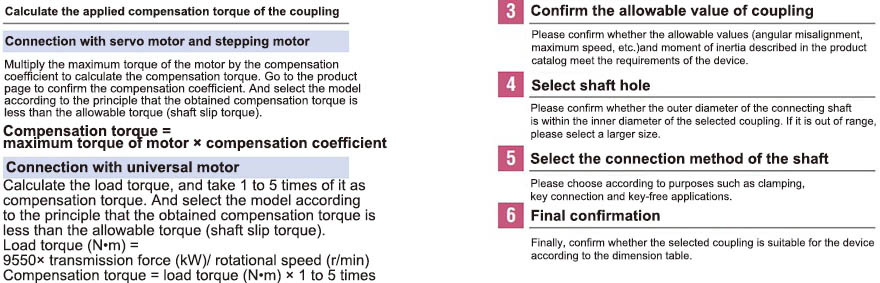

Please order after selecting part number and parameters according to the selection steps to

to  .

.Part Number ( Type· Type· D) D) | - |  d1 d1 | - |  d2 d2 |

| Part Number |  d1, d1,  d2 selection (But d1≤d2) d2 selection (But d1≤d2) | d3 | L | ℓ | t | F | A | Clamp screw·Lock bolt | |||||||||||

Type Type |  D D | M | Tightening Torque | ||||||||||||||||

| (N·m) | |||||||||||||||||||

| GCOC· GCOCRK GCOCLK ·GCOCWK | 16 | *5 | *6 | 7 | 29 | 12.5 | 4 | 3 | 5 | M2.5 | 1 | ||||||||

| 20 | *6 | *6.35 | 8 | 9 | 33 | 14 | 5 | 6.5 | |||||||||||

| 25 | *6.35 | 8 | 10 | 11 | 39 | 16.5 | 6 | 3.8 | 9 | M3 | 1.5 | ||||||||

| 32 | 8 | 10 | 11 | 12 | 14 | 14.5 | 45 | 19 | 7 | 4.5 | 11 | M4 | 2.5 | ||||||

| GCO·GCORK GCOLK·GCOWK | 16 | *3 | *4 | *5 | *6 | *6.35 | 7 | 18 | 7 | 4 | 3.5 | - | M3 | 0.7 | |||||

| 20 | *4 | *5 | *6 | *6.35 | 8 | 9 | 23 | 9 | 5 | 4.5 | M4 | 1.7 | |||||||

| 25 | *5 | *6 | *6.35 | 8 | 10 | 11 | 28 | 11 | 6 | 5.5 | M5 | 4 | |||||||

| 32 | 8 | 10 | 12 | 14 | 14.5 | 33 | 13 | 7 | 6.5 | M6 | 7 | ||||||||

d1 and d2*marked products without keyway hole.

d1 and d2*marked products without keyway hole.■The Coupling Characteristic Value

| Part Number | Allowable torque (N·m) | Allowable Angular Misalignment (°) | Allowable lateral misalignment (mm) | Maximum rotational speed (r/pm) | Moment of inertia (kg·m3) | Weight (g) | |

| Type | D | ||||||

| GCOC·GCOCRK GCOCLK·GCOCWK | 16 | 0.7 | 3 | 1.0 | 10000 | 4.4×10-7 | 11 |

| 20 | 1.2 | 1.5 | 1.2×10-6 | 20 | |||

| 25 | 2.0 | 2.0 | 3.3×10-6 | 37 | |||

| 32 | 4.5 | 2.5 | 1.4×10-6 | 70 | |||

| GCO· GCORK GCOLK ·GCOWK | 16 | 0.7 | 3 | 1.0 | 10000 | 2.2×10-7 | 6 |

| 20 | 1.2 | 1.5 | 6.9×10-7 | 13 | |||

| 25 | 2.0 | 2.0 | 2.1×10-6 | 23 | |||

| 32 | 4.5 | 2.5 | 6.5×10-6 | 45 | |||

Moment of inertia and weight are the values at the maximum shaft dia.

Moment of inertia and weight are the values at the maximum shaft dia. Operating temperature: -20℃ to 80℃

Operating temperature: -20℃ to 80℃ In order to obtain a larger allowable angular misalignment, this product is designed exclusively by MISUMI. For details, please refer to the shape of the protruding part of the adjusting ring GCOCS.

In order to obtain a larger allowable angular misalignment, this product is designed exclusively by MISUMI. For details, please refer to the shape of the protruding part of the adjusting ring GCOCS.Product Features

Precautions

Usage Method

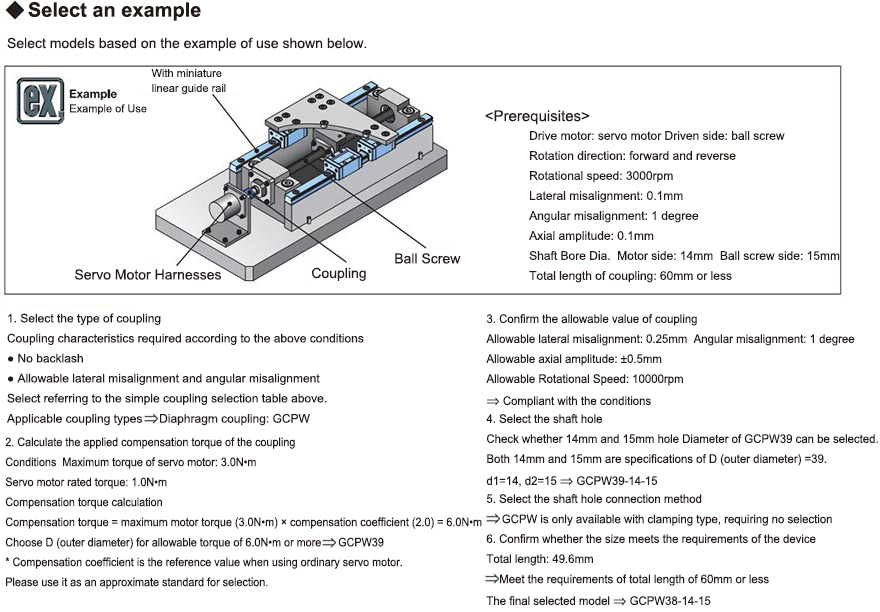

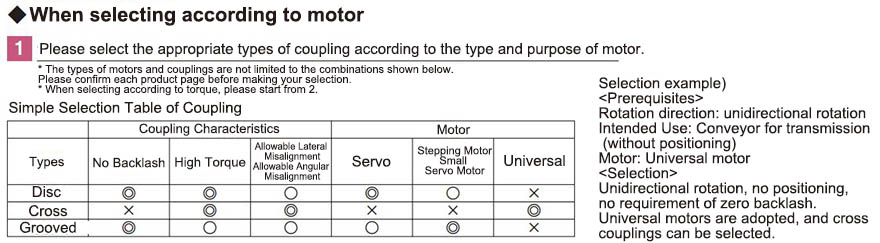

Example of Use