(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- การยกเลิกจำหน่ายสินค้าประเภทอุปกรณ์นิวเมติกส์ (Pneumatic equipment) รุ่น “Economy Series” | Notice of End of Sales for Economy Series Pneumatic Equipment Category > คลิก

MISUMI Metal Washers, Collars(Thickness / Length Tolerance:0~-0.2)

Configure

Specification/Dimensions

-

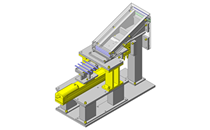

I.D. Shape

-

Straight

Straight -

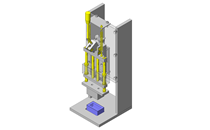

Counterbored

Counterbored -

Tapped

Tapped -

Flat Head Screw

Flat Head Screw -

Screw Hole

Screw Hole -

Slotted Hole, Notched

Slotted Hole, Notched -

2-Hole

2-Hole

-

-

O.D.(mm)

- 3

- 3.2

- 3.35

- 3.65

- 3.8

- 4

- 4.2

- 4.5

- 5

- 5.2

- 5.3

- 5.5

- 6

- 6.3

- 6.4

- 6.5

- 7

- 7.5

- 7.8

- 8

- 8.5

- 9

- 9.5

- 10

- 10.5

- 11

- 11.5

- 12

- 12.2

- 12.5

- 13

- 13.5

- 13.8

- 14

- 14.5

- 15

- 15.5

- 16

- 16.5

- 17

- 17.3

- 17.5

- 18

- 18.5

- 19

- 19.5

- 20

- 20.5

- 21

- 21.5

- 21.7

- 22

- 22.5

- 23

- 23.5

- 24

- 24.5

- 25

- 25.5

- 26

- 26.5

- 27

- 27.2

- 27.5

- 28

- 28.5

- 29

- 29.5

- 30

- 30.5

- 31

- 31.5

- 32

- 32.5

- 33

- 33.5

- 34

- 34.5

- 35

- 35.5

- 36

- 36.5

- 37

- 37.5

- 38

- 38.5

- 39

- 39.5

- 40

- 40.5

- 41

- 41.5

- 42

- 42.5

- 42.7

- 43

- 43.5

- 44

- 44.5

- 45

- 45.5

- 46

- 46.5

- 47

- 47.5

- 48

- 48.5

- 48.6

- 49

- 49.5

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

[5-20/0.5mm Unit(s)][21-60/1mm Unit(s)]

-

I.D.(mm)

- 0

- 1

- 1.5

- 2

- 2.2

- 2.35

- 2.5

- 2.6

- 2.65

- 2.7

- 2.8

- 3

- 3.2

- 3.5

- 4

- 4.1

- 4.2

- 4.3

- 4.5

- 5

- 5.1

- 5.2

- 5.3

- 5.5

- 5.7

- 6

- 6.2

- 6.3

- 6.4

- 6.5

- 6.6

- 7.1

- 7.8

- 8

- 8.2

- 8.4

- 9

- 9.2

- 9.4

- 10

- 10.2

- 10.5

- 10.9

- 11

- 12

- 12.7

- 13

- 14.3

- 15

- 16

- 16.1

- 17

- 19.4

- 20

- 21.4

- 21.6

- 25

- 27.2

- 27.6

- 30

- 32.9

- 35.5

- 35.7

- 38.4

- 41.2

- 41.6

[3-90/0.5mm Unit(s)]

-

Thickness/Length(mm)

- 1

- 1.5

- 1.6

- 2

- 2.5

- 3

- 3.5

- 4

- 4.5

- 5

- 5.5

- 6

- 6.5

- 7

- 7.5

- 8

- 8.5

- 9

- 9.5

- 10

- 10.5

- 11

- 11.5

- 12

- 12.5

- 13

- 13.5

- 14

- 14.5

- 15

- 15.5

- 16

- 16.5

- 17

- 17.5

- 18

- 18.5

- 19

- 19.5

- 20

- 22

- 24

- 25

- 28

- 30

- 32

- 35

- 40

- 42

- 45

- 50

- 52

- 54

- 60

- 100

[1-10/0.1mm Unit(s)]

-

Shape

-

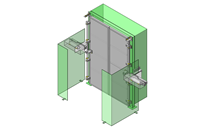

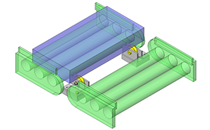

Straight

Straight -

Flanged

Flanged -

Square

Square

-

-

Material

-

Surface Treatment

- Not Provided

- Black Oxide

- Electroless Nickel Plating

- Low Temperature Black Plating

- Anodize (Clear)

- Anodize (Black)

- Trivalent Chromate (Black)

- Trivalent Chromate (White)

-

I.D. Tolerance

-

Thickness / Length Tolerance

-

O.D. Tolerance

-

Sale Type

- Single Item

- Bulk Package

Brand |

|

|---|---|

| CAD |

|

- 2 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

Metal Washers - Thickness +-0.005 - +-0.30 mm Selectable

MISUMI

Use this product in environments where the thickness accuracy is required.Days to Ship: 4 Day(s)

4 Day(s)

-

You can add up to 6 items per a category to the compare list.

![[Clean & Pack]Metal Washer - T Dimension Tolerance Selectable](//content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/t_misumi_wm/v1/p/jp/product/series/110310643319/110310643319_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack]Metal Washer - T Dimension Tolerance Selectable

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products·Degreasing (Anti-rust single packing) : Part Number SL-□□ ·Precision cleaning (Degassing double packing) : Part Number SH-□□ ·Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-rust packing Oil removal General environment Regular assembly process Post battery assembly process SH-□□ Precision cleaning Degassing double packing Oil removal

Dust removalClean environment (Class 10 to 1,000) Battery assembly process LCD-related post assembly process In-vehicle camera assembly process SHD-□□ Electrolytic polishing + precision cleaning Degassing double packing Oil removal

Dust removal

Outgas reductionVacuum environment

Clean environment (Class 10 to 1,000)Pre-semiconductor process Liquid crystal deposition process Pre-OLED process ■Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.Days to Ship: 8 Day(s)

8 Day(s)

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| I.D. Shape |

| O.D.(mm) |

| I.D.(mm) |

| Thickness/Length(mm) |

| Shape |

| Material |

| Surface Treatment |

| I.D. Tolerance |

| Thickness / Length Tolerance |

| O.D. Tolerance |

| Sale Type |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | MISUMI | MISUMI |

| Product Series | [Clean & Pack]Metal Washer - T Dimension Tolerance Selectable | |

| CAD |

|

|

| From | ||

| Days to Ship | 4 Day(s) | 8 Day(s) |

| I.D. Shape | Straight | - |

| O.D.(mm) | 5 ~ 60 | 5 ~ 60 |

| I.D.(mm) | 3 ~ 90 | 3 ~ 90 |

| Thickness/Length(mm) | 1 ~ 10 | 1 ~ 10 |

| Shape | Straight | Straight |

| Material | Stainless Steel ~ Steel | Stainless Steel |

| Surface Treatment | Not Provided / Black Oxide / Electroless Nickel Plating | Not Provided |

| I.D. Tolerance | +0.3~+0.1 | +0.3~+0.1 |

| Thickness / Length Tolerance | 0~-0.2 | 0~-0.2 |

| O.D. Tolerance | 0~-0.2 | 0~-0.2 |

| Sale Type | Single Item | - |

Loading...

Related Categories to Metal Washers, Collars

FAQ Metal Washers, Collars

- Question: What are metal washers and collars used for?

- Answer: Metal washers and collars are essential components in various engineering and mechanical applications. Washers distribute the load of a threaded fastener, such as a bolt or nut, to prevent damage and ensure secure fastening. They can also act as spacers, locking devices, and wear pads. Collars, which are cylindrical spacers, are used to maintain precise positioning of parts on shafts or other components.

- Question: How do I choose the right metal washer or collar for my application?

- Answer: When selecting metal washers or collars, consider the following specifications:

Inner Diameter (I.D.): Ensure it matches the bolt or shaft diameter.

Outer Diameter (O.D.): Should be large enough to distribute the load effectively.

Thickness/Length: Must fit the space and load requirements.

Material: Choose based on environmental conditions (e.g., stainless steel for corrosion resistance).

Surface Treatment: For added protection and durability, treatments like black oxide or nickel plating can be selected. - Question: What materials are metal washers and collars made from?

- Answer: Common materials include:

Stainless Steel: Offers excellent corrosion resistance and strength.

Steel: General-purpose material suitable for most applications.

Brass: Provides good conductivity and resistance to corrosion.

Aluminum: Lightweight and corrosion-resistant, ideal for weight-sensitive applications. - Question: What are the differences between standard and precision grade washers and collars?

- Answer: Standard grade washers and collars are suitable for general use where tight tolerances are not critical. Precision grade options, however, offer tighter tolerances and better surface finishes, making them suitable for high-precision applications where exact dimensions are crucial.

- Question: Can I customize the dimensions of washers and collars?

- Answer: Yes, many suppliers offer customizable options for washers and collars. You can specify the inner and outer diameters, thickness, and even special features like countersunk holes or flanged edges to meet specific application needs.

- Question: What is the significance of surface treatments on metal washers and collars?

- Answer: Surface treatments enhance the performance and longevity of washers and collars by providing additional properties such as corrosion resistance, hardness, or aesthetic appeal. Common treatments include:

Black Oxide: Increases corrosion resistance and reduces light reflection.

Nickel Plating: Provides a smooth, shiny finish with good corrosion resistance.

Anodizing: Commonly used on aluminum for enhanced corrosion resistance and coloring. - Question: How do I ensure the washers and collars meet my tolerance requirements?

- Answer: Specify the tolerance levels when ordering. Standard options include:

Inner Diameter Tolerance: ±0.05 mm to +0.3 mm.

Outer Diameter Tolerance: ±0.1 mm to ±0.3 mm.

Thickness Tolerance: ±0.01 mm to ±0.3 mm. - Question: Are there any special types of washers and collars for specific applications?

- Answer: Yes, there are various specialized types such as:

Countersunk Washers: Designed for use with countersunk screws, allowing the screw to sit flush with the surface.

Flanged Collars: Provide a larger bearing surface, which helps distribute the load over a larger area.

Hardened Washers: Suitable for high-load or high-wear applications due to their increased hardness.

![[Clean & Pack]Metal Washer - T Dimension Tolerance Selectable](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/t_misumi_wm/v1/p/jp/product/series/110310643319/110310643319_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack]Metal Washer - T Dimension Tolerance Selectable](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_c/t_misumi_wm/v1/p/jp/product/series/110310643319/110310643319_001_20230911105917.jpg?$product_view_c$)

How can we improve?

How can we improve?