(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 5:00 21/4/2024 to 5:00 22/4/2024. We apologize for the inconvenience.

- แจ้งวันหยุดทำการในเดือน เมษายน 2567 | Notice holiday in April 2024 > คลิก

C&U Ball Bearings(Size Standards:Metric System)

C&U offers products Ball Bearings specified by Size Standards Metric System from Automation Components product category. There are a total of 2 items. Search and select detailed specifications of parts for your machine with free CAD downloads. C&U products are available to order through MISUMI online 24 hours a day. Free shipping, no minimum order.

Configure

Specification/Dimensions

-

Inner Dia. d(Ø)

- 1

- 1.2

- 1.5

- 2

- 2.5

- 3

- 3.175/0.1250

- 4

- M4

- 4.762/0.1875

- 5

- 6

- M6

- 6.350/0.2500

- 7

- 8

- M8

- 9

- 9.525/0.3750

- 10

- 12

- 12.700/0.5000

- 13

- 14

- 15

- 15.875/0.6250

- 16

- 17

- 18

- 19

- 20

- 22

- 25

- 27

- 28

- 30

- 32

- 35

- 37

- 40

- 42

- 45

- 47

- 50

- 52

- 55

- 57

- 57.150

- 60

- 62

- 65

- 67

- 68

- 70

- 72

- 75

- 77

- 80

- 82

- 83

- 85

- 88

- 90

- 93

- 95

- 100

- 103

- 105

- 110

- 113

- 120

- 123

- 130

- 133

- 140

- 143

- 144

- 150

- 153

- 154

- 160

- 163

- 170

- 180

- 183

- 190

- 200

- 204

- 220

- 224

- 240

- 260

- 280

- 300

- 304

- 320

- 340

- 360

- 380

- 400

- 420

- 440

- 460

- 480

-

Outer Dia. D(Ø)

- 3

- 4

- 5

- 6

- 7

- 8

- 8.1

- 8.2

- 9

- 9.5

- 9.525/0.3750

- 10

- 10.2

- 11

- 11.5

- 11.6

- 12

- 12.2

- 12.5

- 12.700/0.5000

- 13

- 13.5

- 14

- 14.6

- 15

- 15.6

- 15.875/0.6250

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 22.225/0.8750

- 23

- 24

- 25

- 26

- 27

- 28

- 28.575/1.1250

- 30

- 31

- 32

- 34.925/1.3750

- 35

- 37

- 38

- 40

- 42

- 44

- 47

- 50

- 52

- 55

- 56

- 58

- 60

- 62

- 65

- 68

- 70

- 72

- 73

- 74

- 75

- 78

- 80

- 82

- 85

- 90

- 95

- 100

- 105

- 110

- 115

- 120

- 125

- 130

- 135

- 140

- 145

- 149.225

- 150

- 155

- 160

- 165

- 170

- 175

- 180

- 190

- 195

- 200

- 210

- 215

- 220

- 225

- 230

- 235

- 240

- 250

- 260

- 270

- 280

- 290

- 300

- 310

- 320

- 340

- 350

- 360

- 380

- 400

- 420

- 430

- 440

- 460

- 480

- 500

- 520

- 540

- 560

- 580

- 600

- 620

-

Width B(mm)

- 1

- 1.2

- 1.5

- 1.6

- 1.8

- 2

- 2.3

- 2.5

- 2.6

- 2.8

- 3

- 3.5

- 3.967/0.1562

- 4

- 4.5

- 4.978/0.1960

- 5

- 5.5

- 5.8

- 6

- 6.5

- 7

- 7.142/0.2812

- 7.72

- 7.938/0.25

- 7.938/0.3125

- 8

- 8.28

- 8.6

- 8.733/0.3438

- 9

- 9.4

- 9.6

- 10

- 10.4

- 10.5

- 11

- 11.5

- 12

- 12.36

- 13

- 13.64

- 14

- 14.3

- 15

- 15.5

- 15.9

- 16

- 17

- 17.5

- 18

- 19

- 20

- 20.6

- 21

- 22

- 22.2

- 23

- 23.8

- 24

- 25

- 25.4

- 26

- 27

- 28

- 29

- 30

- 30.2

- 31

- 32

- 33

- 33.3

- 34

- 34.9

- 35

- 36

- 36.5

- 37

- 38

- 38.1

- 39

- 39.7

- 40

- 41

- 41.3

- 42

- 43

- 44

- 44.4

- 45

- 46

- 47

- 48

- 49

- 49.2

- 50

- 51

- 52

- 53

- 54

- 54.229

- 55

- 56

- 57

- 58

- 58.7

- 59

- 60

- 61

- 62

- 63

- 63.5

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 92

- 94

- 95

- 96

- 97

- 98

- 99.0

- 100

- 102

- 105

- 107

- 109

- 110

- 112

- 117

- 123

- 128

- 130

- 143

-

Raceway Ring Shape

-

Ball

Ball -

Self-Aligning Ball

Self-Aligning Ball -

Angular Contact Ball (Single Row)

Angular Contact Ball (Single Row) -

Angular Contact Ball (Multi-Row)

Angular Contact Ball (Multi-Row) -

Thrust Ball

Thrust Ball

-

-

Bearing Type

-

Open

Open -

Double Shielded

Double Shielded -

Rubber Sealed

Rubber Sealed -

Single Shielded

Single Shielded

-

-

Outer Ring Type

- Flat

- Spherical

- With V-Shaped Groove

- With U-Shaped Groove

- With Retaining Ring Grooves

- With Flange

- Deep Groove

-

Inner/Outer Ring Material

- Steel

- Stainless Steel

- Plastic

-

Basic Dynamic Load Rating(N)

- 0.6

- 0.64

- 0.66

- 0.7

- 0.73

- 1,080

- 1,330

- 1,456

- 1,590

- 1,610

- 1,910

- 1,992

- 1.28

- 1.34

- 1.46

- 1.89

- 2,130

- 2,160

- 2,240

- 2,340

- 2,690

- 2,784

- 2,890

- 2,944

- 2.02

- 2.56$350000

- 2.8

- 3,350

- 3,400

- 3,440

- 3.01

- 3.19

- 3.26

- 3.57

- 3.92

- 4,080

- 4,300

- 4,310

- 4,320

- 4,480

- 4,550

- 4,750

- 4.27

- 4.48

- 4.76

- 4.94

- 5,100

- 5,600

- 5.43

- 5.74

- 6,390

- 6,400

- 6,800

- 6.58

- 6.72

- 6.79

- 7,600

- 7,750

- 7.07

- 7.98

- 8,200

- 8,300

- 8.65

- 8.96

- 9,400

- 9,600

- 9,700

- 9.24

- 9.45

- 9.8

- 10.6

- 11,400

- 11,900

- 11.13

- 12,800

- 13,500

- 13,800

- 13.65

- 14,000

- 14,800

- 14.84

- 15,900

- 16,000

- 17,800

- 19,500

- 21,800

- 26,700

- 27,000

- 28,500

- 33,500

- 35,000

- 36,000

- 36,500

- 40,000

- 41,500

- 44,500

- 52

- 62,000

- 66

- 67

- 68

- 71,500

- 76,500

- 80

- 85

- 85,000

- 86

- 91

- 92

- 95

- 100

- 100.1

- 102

- 104

- 105

- 106

- 111

- 112

- 120

- 122

- 123.9

- 124

- 124.6

- 125

- 129

- 129.5

- 136

- 138

- 140

- 143

- 144

- 146

- 151.9

- 152

- 153

- 155

- 159

- 167

- 169

- 171

- 174

- 177

- 178

- 185

- 187

- 188

- 191

- 192

- 195

- 196

- 196.7

- 197

- 200

- 201

- 208

- 209

- 212

- 217

- 218

- 221

- 222

- 229

- 229.6

- 231

- 231.7

- 235

- 236

- 237

- 242

- 251

- 255

- 256

- 257

- 258

- 265

- 270

- 273

- 275

- 277

- 278

- 279

- 281

- 282

- 288

- 289

- 292

- 294

- 294.7

- 304

- 308

- 310

- 311

- 319

- 320

- 323.4

- 324

- 325

- 326

- 327

- 328

- 330

- 331

- 331.8

- 332

- 335

- 339

- 339.5

- 340

- 347

- 350

- 355

- 360

- 361

- 365

- 366

- 375

- 375.2$296000

- 380

- 380.8

- 381

- 381.5

- 385

- 386

- 387

- 390

- 392

- 395

- 396

- 399

- 400

- 407

- 408

- 421

- 424

- 424.9

- 430

- 431

- 434

- 438

- 441

- 442

- 448

- 455

- 459

- 462

- 463

- 465

- 468

- 470

- 473

- 474

- 476

- 478.8

- 480

- 484

- 485

- 490

- 495

- 496

- 497

- 500

- 500.5

- 501

- 505

- 510

- 515

- 520

- 535

- 536

- 540

- 541

- 542

- 543

- 544

- 545

- 547

- 550.9

- 552

- 555

- 557.2

- 558

- 560

- 569

- 570

- 571

- 598.5

- 599

- 600

- 604

- 607

- 608

- 630

- 631

- 635

- 640

- 640.5

- 641

- 642.6

- 643

- 648

- 648.2

- 650

- 657

- 658

- 660

- 663

- 669.9

- 670

- 677

- 680

- 684

- 686

- 694

- 697

- 700

- 710

- 711

- 714

- 715

- 716

- 730

- 740

- 755

- 756

- 756$17900

- 770

- 773

- 773.5

- 780

- 784

- 787

- 795

- 796

- 797

- 797.3

- 799

- 800

- 813

- 814

- 815

- 816

- 817

- 820

- 825

- 830

- 850

- 855

- 857

- 859

- 867

- 868

- 874

- 875

- 910

- 912

- 915

- 918

- 919

- 920

- 926

- 928

- 930

- 931

- 936

- 937

- 938

- 940

- 945

- 945$4930

- 957

- 957.6

- 958

- 960

- 969

- 970

- 990

- 995

- 1000

- 1020

- 1021.3

- 1025

- 1028.3

- 1029

- 1038

- 1040

- 1041

- 1046

- 1048

- 1070

- 1077

- 1080

- 1082

- 1091

- 1100

- 1105

- 1120

- 1127

- 1130

- 1131

- 1139

- 1140

- 1142

- 1143

- 1170

- 1173

- 1182

- 1201

- 1210

- 1210.3

- 1211

- 1230

- 1233.4

- 1250

- 1252

- 1280

- 1283

- 1300

- 1301

- 1310

- 1327

- 1329

- 1330

- 1330.7

- 1331

- 1340

- 1340.5

- 1341

- 1344

- 1344.7

- 1350

- 1360

- 1368

- 1369

- 1389.5

- 1390

- 1393

- 1400

- 1402

- 1451

- 1451.1

- 1456

- 1459

- 1460

- 1462

- 1469

- 1470

- 1471

- 1480

- 1509.2

- 1528

- 1533

- 1560

- 1563

- 1563.1

- 1579

- 1590

- 1600

- 1605

- 1610

- 1630

- 1635

- 1635.2

- 1638

- 1650

- 1656

- 1665

- 1686

- 1704

- 1716

- 1717.1

- 1720

- 1729

- 1730

- 1760

- 1762

- 1770

- 1777

- 1790

- 1830

- 1866

- 1883

- 1887

- 1890

- 1900

- 1901

- 1904

- 1910

- 1915

- 1920

- 1921

- 1924

- 1950

- 1959

- 1959.3

- 1983

- 1985

- 1986

- 1989

- 1990

- 1992

- 2020

- 2020.2

- 2030

- 2032

- 2060

- 2070

- 2073

- 2080

- 2090

- 2120

- 2130

- 2150

- 2156

- 2160

- 2176

- 2185

- 2190

- 2230

- 2233

- 2237

- 2240

- 2260

- 2263

- 2290

- 2304

- 2308

- 2321

- 2336

- 2340

- 2345

- 2350

- 2390

- 2450

- 2453

- 2467

- 2480

- 2490

- 2516

- 2530

- 2560

- 2570

- 2570.4

- 2580

- 2593

- 2600

- 2630

- 2645

- 2670

- 2687

- 2690

- 2695

- 2700

- 2710

- 2715

- 2730

- 2750

- 2760

- 2784

- 2799

- 2800

- 2810

- 2810.5

- 2811

- 2831

- 2833

- 2880

- 2883

- 2886

- 2890

- 2900

- 2944

- 3000

- 3010

- 3012

- 3012.1

- 3024.7

- 3025

- 3026

- 3050

- 3190

- 3194

- 3200

- 3211.6

- 3212

- 3222

- 3260

- 3280

- 3287

- 3290

- 3293

- 3300

- 3313

- 3320

- 3327

- 3330

- 3332

- 3333

- 3350

- 3356

- 3399

- 3400

- 3410

- 3430

- 3443

- 3450

- 3470

- 3480

- 3484

- 3500

- 3530

- 3560

- 3570

- 3600

- 3640

- 3650

- 3660

- 3660$8200

- 3666

- 3670

- 3672

- 3680

- 3700

- 3790

- 3840

- 3857

- 3860

- 3868

- 3870

- 3879

- 3900

- 3910

- 3920

- 4000

- 4015

- 4020

- 4050

- 4080

- 4089

- 4100

- 4150

- 4180

- 4185

- 4270

- 4290

- 4300

- 4303

- 4310

- 4320

- 4321

- 4325

- 4330

- 4340

- 4350

- 4400

- 4420

- 4450

- 4466.7

- 4467

- 4480

- 4500

- 4520

- 4538

- 4540

- 4550

- 4560

- 4563

- 4575

- 4588

- 4590

- 4600

- 4620

- 4650

- 4658

- 4659

- 4700

- 4707

- 4720

- 4729

- 4730

- 4740

- 4750

- 4752

- 4760

- 4800

- 4810

- 4837

- 4900

- 4900.7

- 4901

- 4905

- 4923

- 4930

- 4940

- 4950

- 5000

- 5050

- 5060

- 5080

- 5090

- 5100

- 5108

- 5109

- 5200

- 5230

- 5259

- 5300

- 5350

- 5400

- 5420

- 5430

- 5440

- 5450

- 5500

- 5550

- 5580

- 5590

- 5600

- 5610

- 5619

- 5620

- 5690

- 5700

- 5740

- 5750

- 5770

- 5780

- 5800

- 5850

- 5900

- 5950

- 5990

- 5992

- 5999

- 6000

- 6010

- 6100

- 6119

- 6120

- 6150

- 6187

- 6210

- 6250

- 6350

- 6370

- 6374

- 6380

- 6381

- 6390

- 6400

- 6477

- 6480

- 6490

- 6500

- 6580

- 6600

- 6610

- 6650

- 6690

- 6720

- 6750

- 6760

- 6786

- 6790

- 6800

- 6843

- 6870

- 6890

- 6900

- 6950

- 7000

- 7001

- 7002

- 7010

- 7020

- 7050

- 7070

- 7100

- 7150

- 7200

- 7237

- 7242

- 7250

- 7270

- 7280

- 7300

- 7320

- 7350

- 7400

- 7420

- 7450

- 7470

- 7500

- 7520

- 7550

- 7600

- 7610

- 7620

- 7640

- 7650

- 7660

- 7700

- 7750

- 7770

- 7800

- 7840

- 7850

- 7900

- 7950

- 7960

- 7980

- 7990

- 8000

- 8024

- 8030

- 8050

- 8060

- 8080

- 8090

- 8100

- 8130

- 8150

- 8200

- 8240

- 8250

- 8300

- 8330

- 8350

- 8500

- 8520

- 8540

- 8550

- 8580

- 8590

- 8600

- 8630

- 8650

- 8750

- 8800

- 8840

- 8850

- 8960

- 9050

- 9120

- 9200

- 9230

- 9240

- 9265

- 9270

- 9300

- 9310

- 9385

- 9400

- 9440

- 9450

- 9500

- 9540

- 9550

- 9600

- 9650

- 9699

- 9700

- 9710

- 9750

- 9800

- 9870

- 9877

- 9900

- 9950

- 10000

- 10062

- 10100

- 10150

- 10200

- 10240

- 10300

- 10370

- 10400

- 10404

- 10500

- 10570

- 10600

- 10699

- 10700

- 10800

- 10880

- 10900

- 10910

- 11000

- 11100

- 11130

- 11200

- 11220

- 11240

- 11270

- 11300

- 11400

- 11434

- 11500

- 11550

- 11600

- 11620

- 11626

- 11630

- 11690

- 11700

- 11760

- 11800

- 11900

- 11980

- 11985

- 12000

- 12100

- 12110

- 12200

- 12240

- 12300

- 12350

- 12359

- 12400

- 12500

- 12600

- 12700

- 12720

- 12800

- 12900

- 12990

- 13000

- 13100

- 13200

- 13229

- 13300

- 13400

- 13490

- 13500

- 13560

- 13600

- 13621

- 13650

- 13678

- 13700

- 13790

- 13800

- 13890

- 13900

- 14000

- 14014

- 14100

- 14200

- 14250

- 14280

- 14300

- 14400

- 14420

- 14500

- 14540

- 14600

- 14630

- 14700

- 14800

- 14840

- 14900

- 15000

- 15100

- 15150

- 15200

- 15260

- 15300

- 15400

- 15600

- 15700

- 15750

- 15800

- 15900

- 15936

- 15965

- 16000

- 16100

- 16200

- 16400

- 16500

- 16530

- 16600

- 16700

- 16769

- 16800

- 16900

- 17000

- 17200

- 17300

- 17400

- 17490

- 17500

- 17600

- 17765

- 17800

- 17900

- 17990

- 18000

- 18100

- 18200

- 18300

- 18400

- 18500

- 18510

- 18530

- 18600

- 18690

- 18700

- 18800

- 18880

- 18900

- 19000

- 19100

- 19200

- 19300

- 19400

- 19456

- 19460

- 19500

- 19600

- 19700

- 19800

- 19900

- 20000

- 20200

- 20300

- 20370

- 20400

- 20500

- 20584

- 20600

- 20650

- 20700

- 20800

- 20900

- 21000

- 21200

- 21300

- 21400

- 21600

- 21700

- 21800

- 21810

- 21845

- 21900

- 22000

- 22050

- 22100

- 22200

- 22300

- 22400

- 22500

- 22600

- 22630

- 22695

- 22700

- 22800

- 22900

- 23000

- 23100

- 23300

- 23400

- 23450

- 23500

- 23600

- 23700

- 23800

- 23900

- 24000

- 24200

- 24300

- 24400

- 24500

- 24600

- 24730

- 24735

- 24800

- 24900

- 25000

- 25100

- 25200

- 25300

- 25400

- 25600

- 25683

- 25700

- 25900

- 26000

- 26200

- 26300

- 26400

- 26500

- 26700

- 26775

- 26800

- 26900

- 27000

- 27100

- 27300

- 27500

- 27600

- 27790

- 27800

- 27900

- 28000

- 28100

- 28200

- 28300

- 28350

- 28400

- 28475

- 28500

- 28600

- 28800

- 28900

- 29000

- 29100

- 29200

- 29300

- 29400

- 29500

- 29600

- 29700

- 29750

- 29800

- 29900

- 30200

- 30300

- 30400

- 30500

- 30600

- 30700

- 31000

- 31100

- 31200

- 31400

- 31500

- 31800

- 31900

- 32000

- 32100

- 32500

- 32700

- 33000

- 33300

- 33400

- 33500

- 33600

- 33700

- 33800

- 34000

- 34100

- 34425

- 34500

- 34700

- 35000

- 35100

- 35400

- 35500

- 35800

- 36000

- 36200

- 36400

- 36500

- 36800

- 37000

- 37100

- 37200

- 37500

- 37700

- 38000

- 38100

- 38400

- 38500

- 38800

- 39000

- 39400

- 39500

- 39700

- 40000

- 40500

- 40700

- 40800

- 41000

- 41500

- 41600

- 41700

- 42000

- 42300

- 42500

- 42700

- 43000

- 43400

- 43500

- 43600

- 43900

- 44000

- 44500

- 44900

- 45000

- 45050

- 45400

- 45500

- 45700

- 46000

- 46200

- 46300

- 46500

- 47000

- 47500

- 47600

- 48000

- 48500

- 48700

- 49000

- 49400

- 49500

- 50000

- 50500

- 50700

- 50900

- 51000

- 51300

- 51500

- 51800

- 52000

- 52400

- 52500

- 52700

- 53000

- 53400

- 53500

- 54000

- 54200

- 54400

- 54500

- 54600

- 54700

- 55000

- 55300

- 55500

- 55900

- 56000

- 56500

- 57000

- 57200

- 57500

- 57600

- 58000

- 58500

- 58900

- 59000

- 59500

- 59700

- 59900

- 60000

- 60500

- 61100

- 61300

- 61500

- 61800

- 62000

- 62500

- 62800

- 63000

- 63500

- 63700

- 63800

- 64000

- 64500

- 64600

- 65000

- 65200

- 66000

- 66300

- 66500

- 66600

- 67000

- 67300

- 67500

- 67600

- 68000

- 68400

- 68500

- 68900

- 69000

- 69300

- 69500

- 69800

- 70000

- 70200

- 70500

- 70600

- 70900

- 71000

- 71500

- 72000

- 72400

- 72500

- 72800

- 72900

- 73000

- 73500

- 73800

- 74000

- 74100

- 74500

- 75000

- 75300

- 75500

- 76000

- 76100

- 76500

- 77000

- 77500

- 78000

- 78500

- 79000

- 79100

- 79200

- 79300

- 79500

- 80000

- 80500

- 80600

- 81500

- 81900

- 82000

- 83000

- 83500

- 84000

- 84500

- 85000

- 85200

- 85300

- 86000

- 86500

- 86700

- 87000

- 87100

- 87200

- 87500

- 88000

- 88400

- 88500

- 88600

- 89000

- 90000

- 91000

- 91400

- 92000

- 92500

- 93000

- 93500

- 93600

- 94000

- 94500

- 95000

- 95500

- 95600

- 95700

- 96000

- 96500

- 97000

- 97500

- 98000

- 98500

- 98600

- 99000

- 99500

- 100000

- 101000

- 102000

- 103000

- 104000

- 105000

- 106000

- 107000

- 108000

- 109000

- 110000

- 111000

- 112000

- 113000

- 114000

- 115000

- 116000

- 117000

- 118000

- 119000

- 120000

- 121000

- 122000

- 123000

- 124000

- 125000

- 126000

- 127000

- 128000

- 129000

- 130000

- 131000

- 133000

- 134000

- 134260

- 135000

- 136000

- 137000

- 138000

- 139000

- 140000

- 141000

- 142000

- 143000

- 144000

- 145000

- 146000

- 147000

- 148000

- 149000

- 151000

- 152000

- 153000

- 154000

- 155000

- 156000

- 157000

- 159000

- 160000

- 161000

- 162000

- 164000

- 165000

- 166000

- 167000

- 168000

- 170000

- 171000

- 172000

- 173000

- 174000

- 175000

- 176000

- 177000

- 178000

- 179000

- 180000

- 181000

- 182000

- 183000

- 184000

- 185000

- 186000

- 187000

- 188000

- 189000

- 190000

- 191000

- 192000

- 193000

- 194000

- 196000

- 197000

- 198000

- 199000

- 201000

- 202000

- 203000

- 204000

- 205000

- 207000

- 208000

- 209000

- 210000

- 211000

- 212000

- 214000

- 217000

- 218000

- 219000

- 220000

- 221000

- 222000

- 223000

- 224000

- 225000

- 226000

- 227000

- 228000

- 229000

- 231000

- 232000

- 233000

- 234000

- 235000

- 236000

- 237000

- 238000

- 239000

- 240000

- 241000

- 244000

- 245000

- 246000

- 248000

- 249000

- 250000

- 252000

- 253000

- 254000

- 255000

- 258000

- 260000

- 261000

- 263000

- 264000

- 266000

- 269000

- 270000

- 272000

- 273000

- 274000

- 275000

- 276000

- 277000

- 278000

- 280000

- 282000

- 284000

- 287000

- 289000

- 291000

- 295000

- 296000

- 297000

- 300000

- 305000

- 310000

- 315000

- 320000

- 325000

- 330000

- 335000

- 340000

- 345000

- 350000

- 355000

- 360000

- 365000

- 370000

- 375000

- 380000

- 390000

- 395000

- 400000

- 405000

- 410000

- 415000

- 420000

- 430000

- 435000

- 440000

- 450000

- 455000

- 460000

- 465000

- 475000

- 480000

- 510000

- 525000

- 530000

- 540000

- 545000

- 550000

- 585000

- 595000

- 640000

-

Specifications, Environment

- Standard

- Heat Resistant

- Water Resistant

- Abrasion Resistant

- Non-magnetic

- Antirust

- Dust Resistant

- For Vacuum

- Highly Durable

- For High Speed

- Corrosion Resistant

-

Precision (JIS)

- Class 0

- Class 2

- Class 4

- Class 5

- Class 6

-

Load Direction

-

Rolling Element Material

-

Size Standards

-

Number of Raceway Ring Rows

-

Clearance Symbol

- CN (Standard)

- C3

Brand |

|

|---|---|

| CAD |

|

- 2 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

Deep Groove Ball Bearing, Inner Diameter ø10 to 50

C&U

A broad lineup available with inner diameters ranging from ø10 to 50.

Suitable for a range of applications, including for ball screws, wheels and chain conveyors.

[Features]

· Developed based on standards that focus on versatility and high-frequency use

· International items at a low price. Recommended for those concerned with reducing costs.From: ฿ 119.05 Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

Small Diameter Ball Bearing - Double Shielded -

C&U

We offer a lineup with inner diameter sizes ranging from ø3 to 8.

Suitable for a range of applications, including for ball screws, wheels and chain conveyors.

[Features]

· Developed based on standards that focus on versatility and high-frequency use

· International items at a low price. Recommended for those concerned with reducing costs.From: ฿ 72.39 Days to Ship: Same day

Same day

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Inner Dia. d(Ø) |

| Outer Dia. D(Ø) |

| Width B(mm) |

| Raceway Ring Shape |

| Bearing Type |

| Outer Ring Type |

| Inner/Outer Ring Material |

| Basic Dynamic Load Rating(N) |

| Specifications, Environment |

| Precision (JIS) |

| Load Direction |

| Rolling Element Material |

| Size Standards |

| Number of Raceway Ring Rows |

| Clearance Symbol |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | C&U | C&U |

| Product Series | ||

| CAD |

|

|

| From | ฿ 119.05 | ฿ 72.39 |

| Days to Ship | Same day | Same day |

| Inner Dia. d(Ø) | 10 ~ 50 | 3 ~ 8 |

| Outer Dia. D(Ø) | 19 ~ 90 | 7 ~ 24 |

| Width B(mm) | 5 ~ 23 | 3 ~ 8 |

| Raceway Ring Shape | Ball | Ball |

| Bearing Type | Double Shielded | Double Shielded |

| Outer Ring Type | Flat | Flat |

| Inner/Outer Ring Material | Steel | Steel |

| Basic Dynamic Load Rating(N) | 1350 ~ 40500 | 390 ~ 4000 |

| Specifications, Environment | Standard | Standard |

| Precision (JIS) | Class 0 | Class 0 |

| Load Direction | Radial | Radial |

| Rolling Element Material | Steel | Steel |

| Size Standards | Metric System | Metric System |

| Number of Raceway Ring Rows | Single Row | Single Row |

| Clearance Symbol | - | - |

Loading...

Related Categories to Ball Bearings

FAQ Bearing

- Question: How to select the right ball bearing for your application

- Answer: 1. Choose a bearing that is fit to the "Bore" and "Shaft’s diameter" for not being loose in installation and causing misalignment.

2. Choose a bearing that is matched to the shaft's rotating speed to reduce heat in the "Ball" and "Ring" that will make bearings deteriorate.

3. Choose a bearing that is matched to the "radial load" and "axial load" of the application.

4. Choose a bearing that has clearance that matches the temperature in the operation area, like the conveyor of a furnace, because "Ball" and "Ring" will expand from heat and create more.

5. Choose a bearing that is compatible with the environment of the operation area, like a bearing that has a dust cover to prevent dust from creeping in or a bearing that is capable of heat resistance. - Question: What are bearing types and their various applications

- Answer: Normally, bearing can be divided into 2 groups:

1. Rolling-element bearings that contain "Balls" or "Rollers" between the "Outer - Inner Rings" to carry loads These bearings have 2 types.

1.1. Ball bearing: use balls as rolling elements. It can take bolt "Radial Load" and "Axial Load". Example: Bearing in a Bicycle’s Wheel.

1.2. Roller bearing: use rollers as rolling elements. Good to carry "Radial Load". Example: Bearing in the Conveyor’s Pulley.

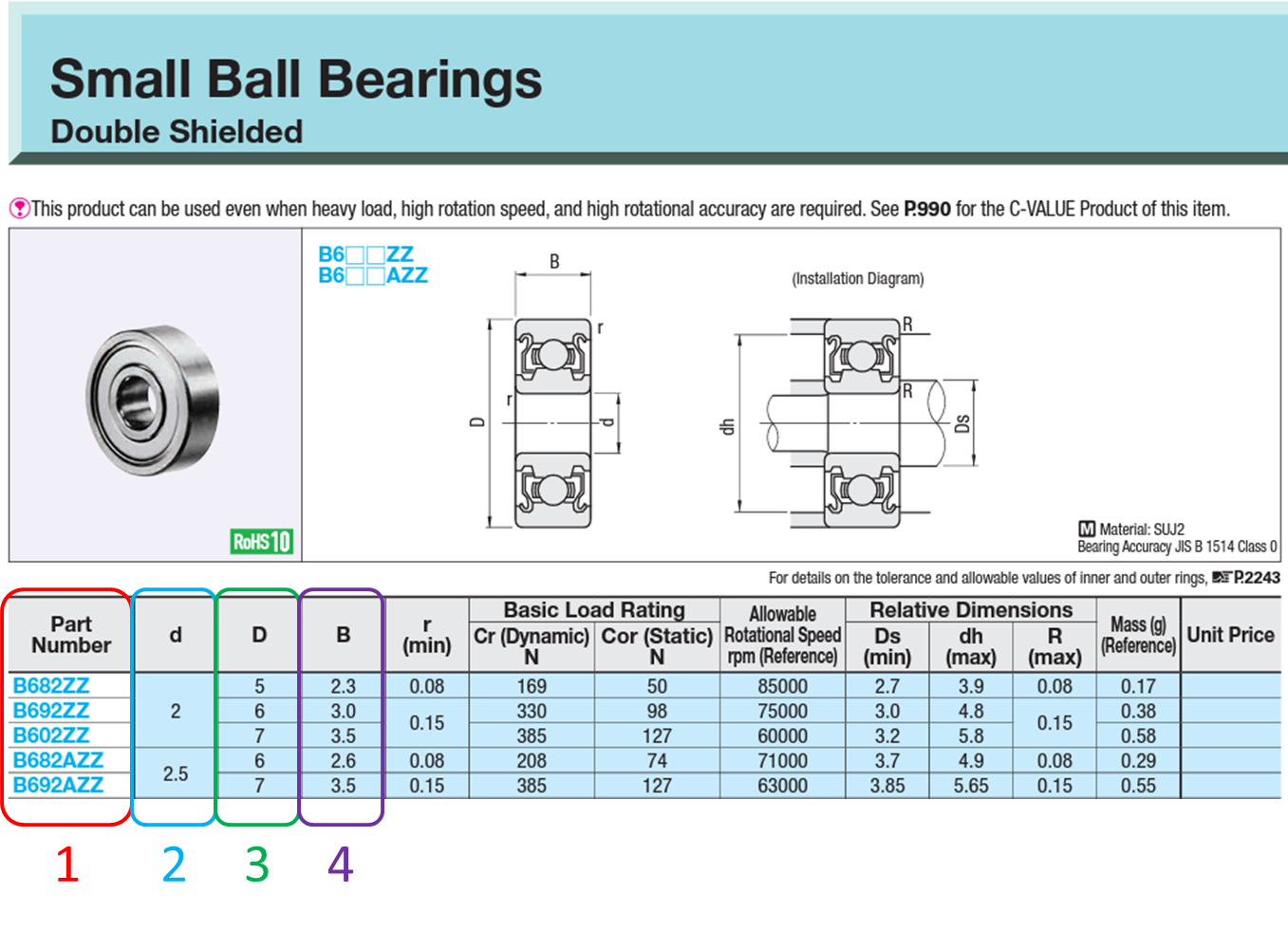

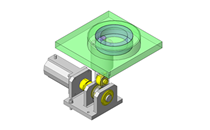

2. Plain bearing: It has 2 components. 1st is "Journal" which is a hollow cylinder case, and "Journal Bearing" which is an inside bore. This plain bearing uses oil as lubrication and is capable of self-alignment. Good for low rotating speed and eccentric force like an excavator cylinder rod end. - Question: How to read and use a ball bearing size chart? Please use this picture

- Answer:

Basically, bearing size tables contain 4 columns.

- 1st column is Part Number.

- 2nd column is "Inside Diameter" or “d” which tells the size of the shaft.

- 3rd column is "Outside Diameter" or “D” which tells the size of the bore.

- 4th column is “Bore” or “B” which tells the width of the bearing so that it can be installed properly.

- Some types of bearing size chart might have other columns for more detail. Such as rotating speed, basic load rating, mass etc.

The above information is referenced from Product catalog from MISUMI. In some manufacturers, the order of the tables may slightly change. - Question: Whar are bearing materials and their properties

- Answer: - Carbon steel is the cheapest and strongest, but the material has low heat resistance and is not able to take high loads or a high rotating speed.

- Chrome steel is stronger and able to take a higher load than carbon steel, but it requires lubrication. and the material is not resistant to chemicals and corrosion.

- Stainless steel has high efficiency, strong, and resistant to corrosion. but it’s heavy, requires lubrication. and expensive.

- Ceramic have high-temperature resistant, resistant to corrosion and light weight. but load capacity is lower than steel Bearing.

- Polymer have many varieties: nylon, polyethylene (PE), etc. The Polymer’s bearing has low-friction properties, light weight, resistance to rust. but it’s expensive and low of heat resistance.

- Hybrid is created by combining materials for the highest load capacity. capable of being heat-resistant and be able to work under conditions of high rotating speed. But it’s extremely expensive and hard to find. So, it has been used for specific applications only. - Question: How to troubleshoot common problems with ball bearings

- Answer: 1. Flaking: Mostly, this problem arises from fractions that creep into bearing. made the ball/Roller or roller scratch with internal parts. This could be prevented by using bearings that have a dust cover and lubricating them with grease.

2. Rusting: The source of this problem comes from water/humidity that gets inside the bearing. Lubrication by using grease is going to coat the bearing’s surface and prevent contact with humidity in the air.

3. Cage distortion: Mostly, this problem comes from drop bearings. But in any case, misassembling is also the cause of the problem. Example Clearance after assembly is not up to standard. Made it to have a gap that balls bump with cage.

4. Fracture: This could be caused by many reasons, but in summary, it is caused by bearings taking a higher load than is allowable. like using the wrong type of bearing or a machine working in the wrong condition. - Question: What distinguishes a simple ball bearing from a deep groove ball bearing?

- Answer: Deep Grove Ball Bearings have a raceway that fits the size of the balls. That’s made the Deep Grove Ball Bearing more stable and able to take a higher load than a normal bearing. Still, it has low-friction properties and can take both radial and axial loads.

How can we improve?

How can we improve?