(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- inCAD Library Home

- > No.000217 Low Impact Clamping Mechanism

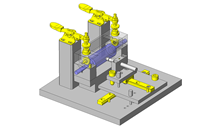

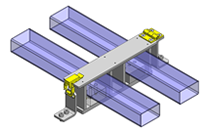

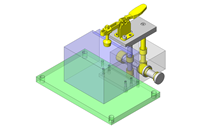

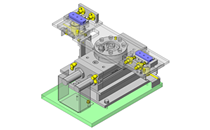

No.000217 Low Impact Clamping Mechanism

Low-impact clamp.

Relevant category

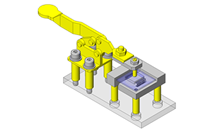

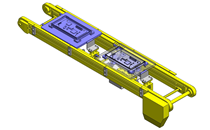

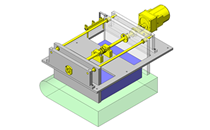

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

- Purpose

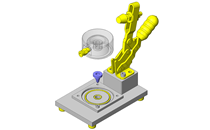

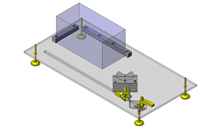

- To clamp workpieces that are vulnerable to impact.

- Operation

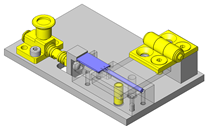

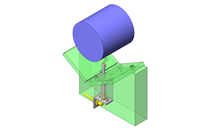

- Slide shaft mechanism in clamp helps prevent hard impact of the workpiece being clamped.

- To release the workpiece, first release the knob to disengage the slide shaft, then lift the clamp.

Points for use

- Manual operation

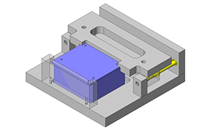

Target workpiece

- Shape: glass circuit board

- Size: W65 x L130 x H0.7mm

- Weight: 10.6g

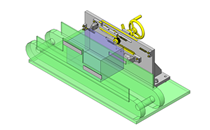

Design Specifications

Operating Conditions or Design Requirements

- Slide shaft stroke: 10mm

Arm rotation angle: 90° - Outer dimensions: W200 x D380 x H144mm

Required Performance

- Clamping force: 3 to 4N

Selection Criteria for Main Components

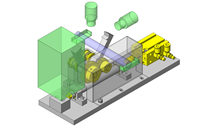

- A spring with a spring constant k = 0.16N/mm that satisfies the workpiece clamping force requirement of 3 to 4N is selected.

Design Evaluation

Verification of main components

- The clamping force is verified based on the load moment.

- Confirmation of workpiece clamping force

- Conditional value: distance between rotary shaft and center of gravity of arm Lg = 87.4mm, angle formed by rotary shaft and center of gravity of arm α = 15.3°, mass of arm M = 436.9g, gravitational acceleration g = 9.8m/s2, distance between rotary shaft and spring post of arm Lk1 = 95.52mm, angle formed by spring post of link base and spring post of arm and rotary shaft β = 20.69°, distance between spring post of link base and spring post of arm Lk2 = 111.4mm, spring constant k = 0.16N/mm, free length of tension spring Lk0 = 100mm, initial tension of spring F1 = 2.94N, number of springs n = 2 pieces, distance between rotary shaft and clamping part La = 201mm, angle formed by rotary shaft and clamping part γ = 3.27°

- Moment produced by arm mass: Mm = (M x g x cosα) x Lg, hence, Mm = 436.9 x 10?3 x 9.8 x 0.964 x 87.4 = 360.74N・mm

Moment produced by tension spring: Mk = {k x (Lk2 - Lk0) + F1} x sinβ x Lk1 x n, hence, Mk = {0.16 x (111.4 - 100) + 2.94} x 0.353 x 95.52 x 2 = 321.26N・mm - Comparison of moment

If we put F as the force of the clamping part and Ma as the moment of the clamping part, from Mm + Mk = Ma = F x cosγ x La, F = (Mm + Mk)/(cosγ x La), hence, F = (360.74 + 321.26)/(0.998 x 201) = 3.39N

-> The clamping force is within the target range (3 to 4N).

Other Design Consideration

- The shape of the stopper makes it possible to fix the slide shaft during clamping, and it is automatically returned by the coil spring built in the spring plunger during unclamping.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category