(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- inCAD Library Home

- > No.000178 Feed Mechanism for Bar-shaped Workpieces

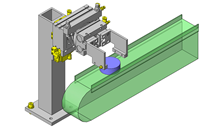

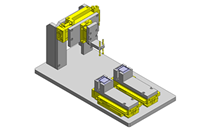

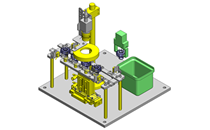

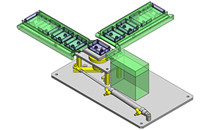

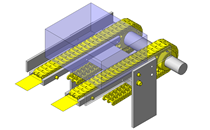

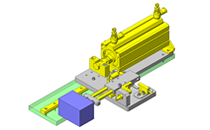

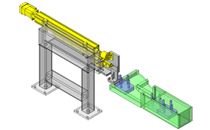

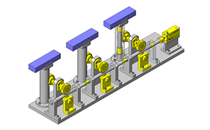

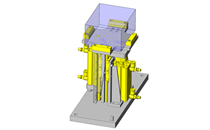

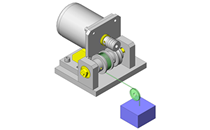

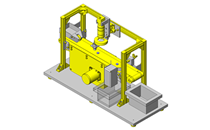

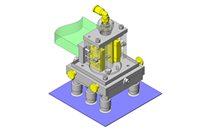

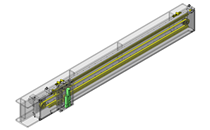

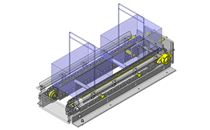

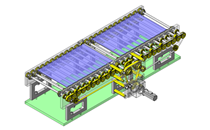

No.000178 Feed Mechanism for Bar-shaped Workpieces

17

17

Separates out bar-shaped parts

Relevant category

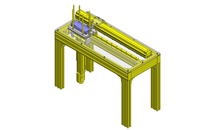

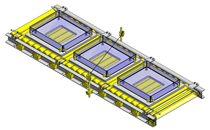

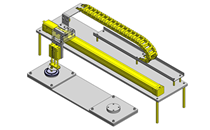

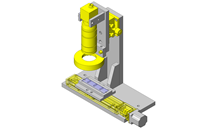

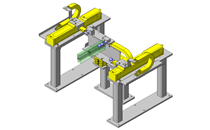

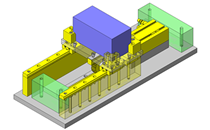

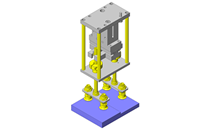

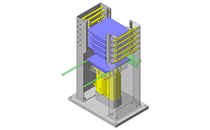

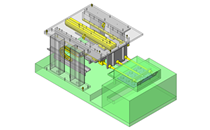

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

- Purpose

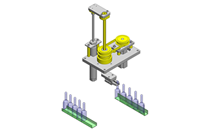

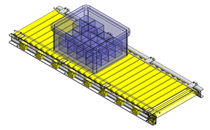

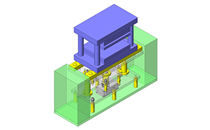

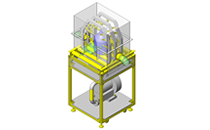

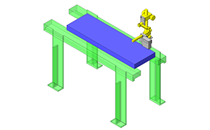

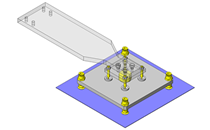

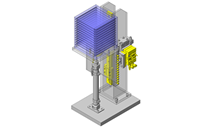

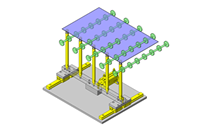

- Magazine stores workpieces until they are cut. Once cut they are transferred by a robot.

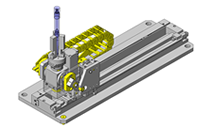

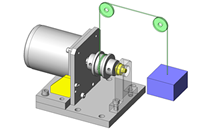

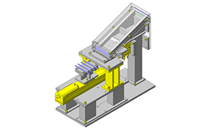

- Operation

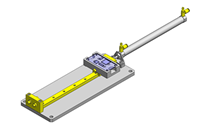

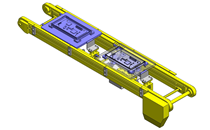

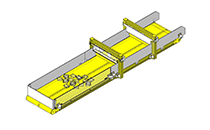

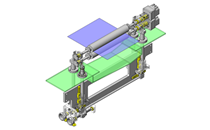

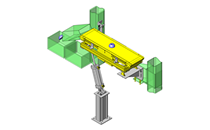

- Workpiece moves into groove on slide plate. A guided cylinder moves the slide plate forward to a robot. The next workpiece is held in the magazine by the upper surface of the slide plate as the plate moves. Once the slide plate retracts, the next workpiece falls into the groove.

Points for use

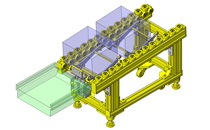

- Workpieces are manually fed into the magazine.

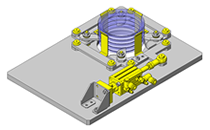

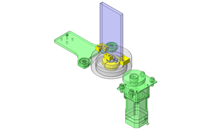

Target workpiece

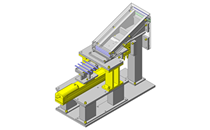

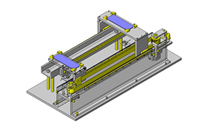

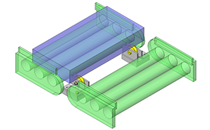

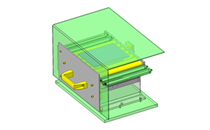

- Shape: Plastic bar with metal inserted on the tip

- Size: φ 3.15 x L 140 mm

- Weight: 5 g

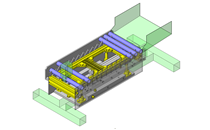

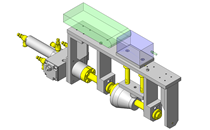

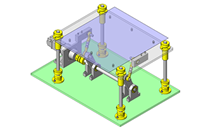

Design Specifications

Operating Conditions or Design Requirements

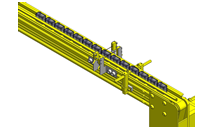

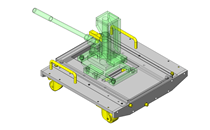

- Stroke: 90 mm

- External size: W 390 x D 218 x H 208 mm

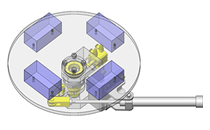

Required Performance

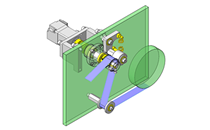

- Locating accuracy of the robot hand: ± 0.2 mm

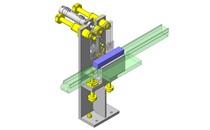

Selection Criteria for Main Components

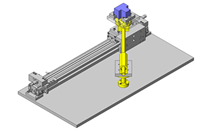

- Select guide cylinder based on load and stoke needed.

Design Evaluation

Verification of main components

- Compare the table displacement under load to the robot locating accuracy.

- Check the accuracy of the guided cylinder

- Conditional values: Stroke of the slide plate: S = 90 mm

Slide plate weight: M = 0.53 kg - Table displacement listed in the catalogue: Read the displacement at the tip of the table from the graph when the load (F1) is applied on the table tip.

- No description is provided in the graph for the case where load (F1) = 40N or lower. Assuming load (F1) = 40N by adding stroke and slide plate weights, displacement at the tip of the table is 0.02mm.

- Sufficient accuracy for the robot hand locating accuracy of ± 0.2mm.

- Conditional values: Stroke of the slide plate: S = 90 mm

Other Design Consideration

- The upper portion of the slide plate holds the next workpiece in the magazine as the plate slides. Make sure the slide plate has a buffed finish to help reduce the friction between the next workpiece and the slide plate.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category

-

Relevant category