(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- inCAD Library Home

- > No.000163 Simplified Indexing Table

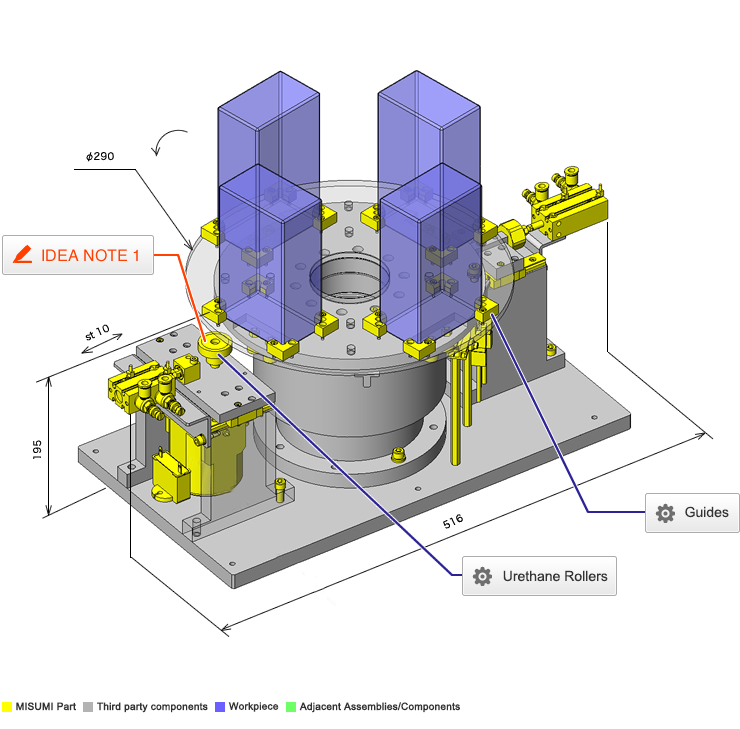

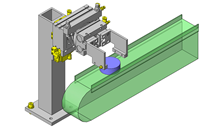

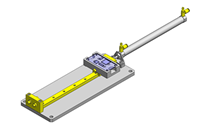

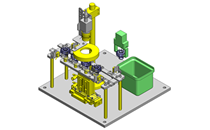

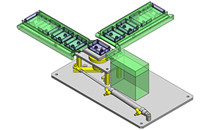

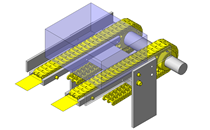

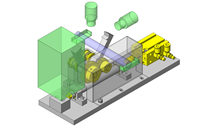

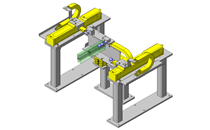

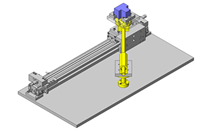

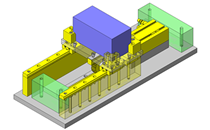

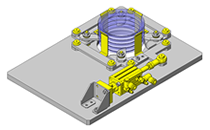

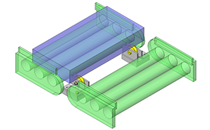

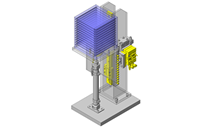

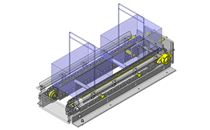

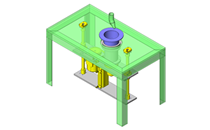

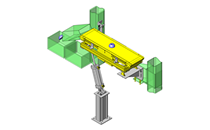

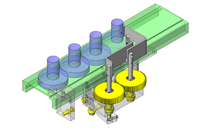

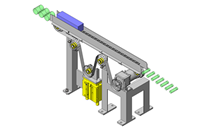

No.000163 Simplified Indexing Table

35

35

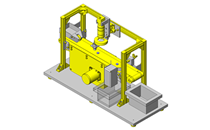

Cost effective indexing table.

Relevant category

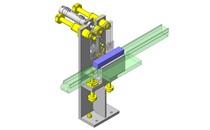

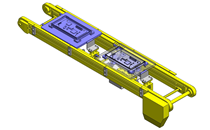

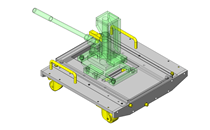

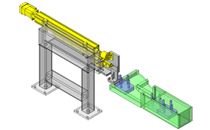

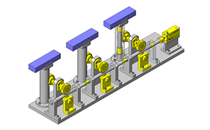

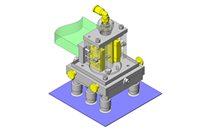

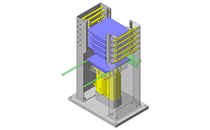

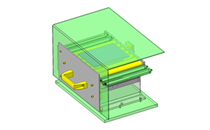

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

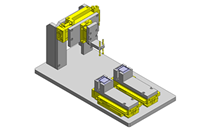

Application Overview

Purpose

- Purpose

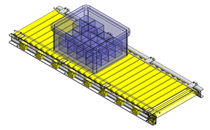

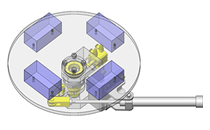

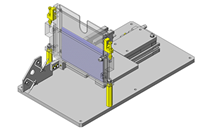

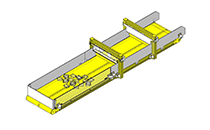

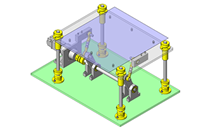

- Indexing table used in magazine transfer.

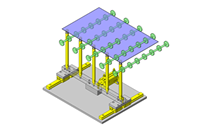

- Operation

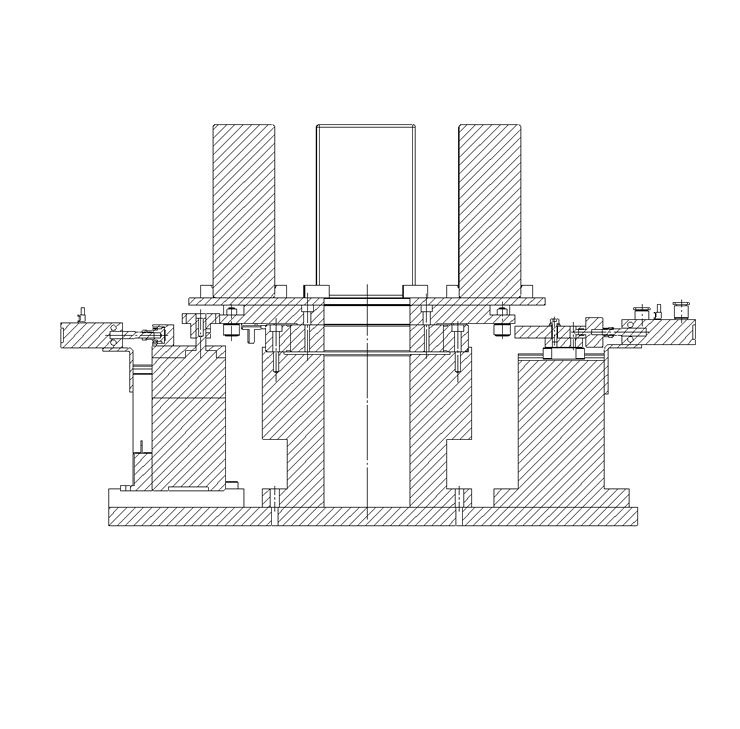

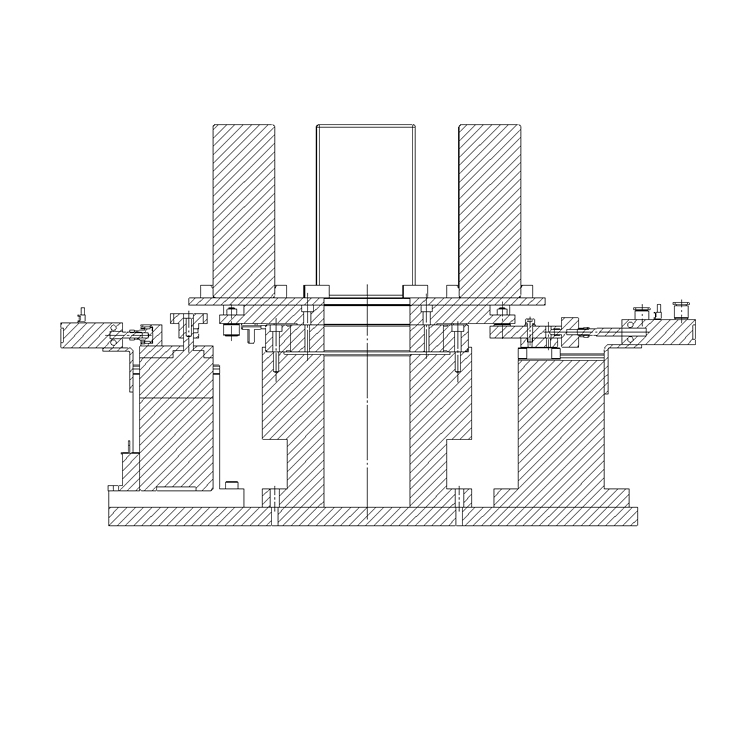

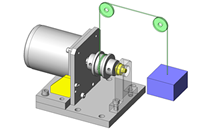

- A geared motor drives a urethane roller which turns the indexing table. A deceleration sensor is used in conjunction with a stop sensor to slowly bring the table to a stop. A wedge is used to physically top the rotation of the table.

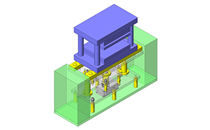

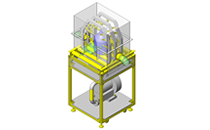

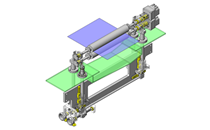

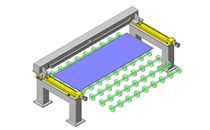

Points for use

- Disengage the indexing table during maintenance.

The indexing table is operated slowly.

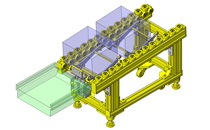

Target workpiece

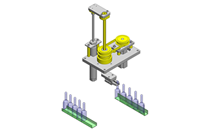

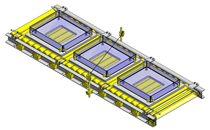

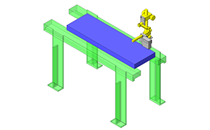

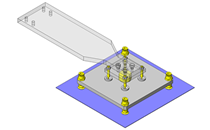

- Shape: Magazine

- Size: W80xD50xH140mm

- Weight: 1.5kg

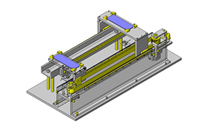

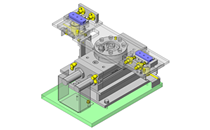

Design Specifications

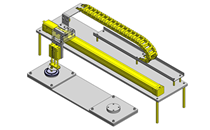

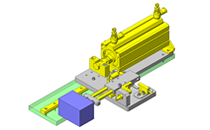

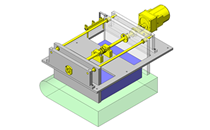

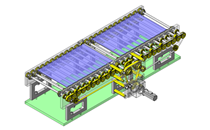

Operating Conditions or Design Requirements

- Index table outer diameter: φ290mm

- 4 positions

- Cycle time: 1 second for 1 position

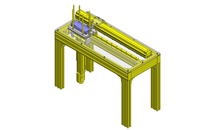

- Outer dimensions: W516xD290xH195mm

Required Performance

- Positioning accuracy: ±0.5mm

- Load weight: 1.5×4=6kg

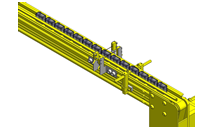

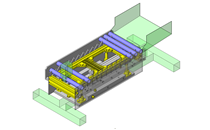

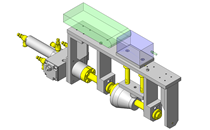

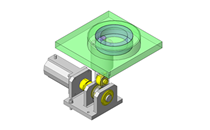

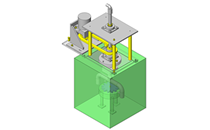

Selection Criteria for Main Components

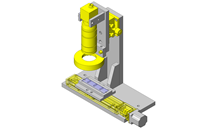

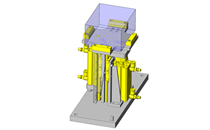

- Variable geared motor

- As the index table cycle time t is 1 second per position, it takes 4 seconds to rotate one revolution. Therefore, the table rotation speed Nt is 15 rpm.

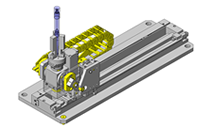

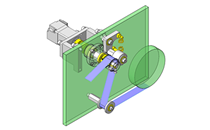

- As the outer diameter D1 of the part driven by the urethane roller of the geared motor is φ240 and the diameter D2 of the urethane roller of the geared motor is φ30, the rotation speed N of the geared motor is D1/D2 x Nt = 240/30 x 15 = 120rpm.

- A variable geared motor with a variable range of 90 to 1200rpm and a gear head with a reduction ratio i of 1/3 are selected, and the range of variable rotation speed after deceleration should be set to 30 to 400.

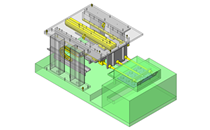

Design Evaluation

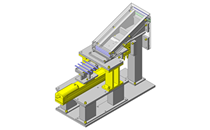

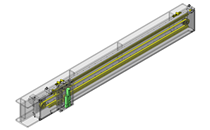

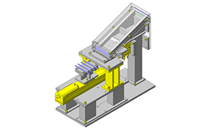

Verification of main components

- Need to ensure the geared motor allowable torque satisfies the necessary load torque.

- Confirmation of load torque of geared motor

- Conditional value: index table rotation speed: Nt = 15 rpm, outer diameter of table driven part: D1 = φ240mm, diameter of the urethane roller of geared motor: D2 = φ30mm, cycle time: t = 1sec, moment of inertia of rotating part including workpiece: J = 0.083kg・m2

- Rotation speed of geared motor: N = D1/D2 x Nt = 240/30 x 15 = 120rpm

- Load torque of geared motor: T = J/(9.55 x 104) x N/t = 0.083/(9.55 x 104) x 120/1 = 1.04 x 10??N・m

- Allowable torque of geared motor when gear head is mounted (when reduction ratio i = 1/3): Tmax = 0.06N・m

⇒Load torque: T = 1.04 x 10??N・m

< allowable torque: Tmax = 0.06N・m Therefore, the load torque of geared motor is within the allowable range.

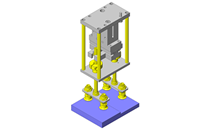

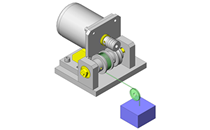

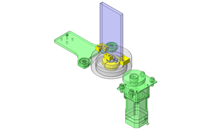

- Confirmation of gear head overhang load

- As the allowable overhang load of the gear head used in this device is 98N at the output shaft center, the allowable overhang load of this device is 98N x 16mm/32mm = 49N.

⇒φAs the theoretical thrust of φ16 cylinder on the push side is 40N when the operating pressure is 0.2MPa, the cylinder that presses against motor is used at 0.2MPa.

- As the allowable overhang load of the gear head used in this device is 98N at the output shaft center, the allowable overhang load of this device is 98N x 16mm/32mm = 49N.

Other Design Consideration

- Micro photo sensor is used as a confirmation and deceleration sensor.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category

-

Relevant category