(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- inCAD Library Home

- > No.000131 Fitting Jig

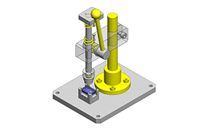

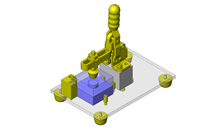

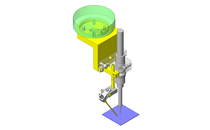

No.000131 Fitting Jig

17

17

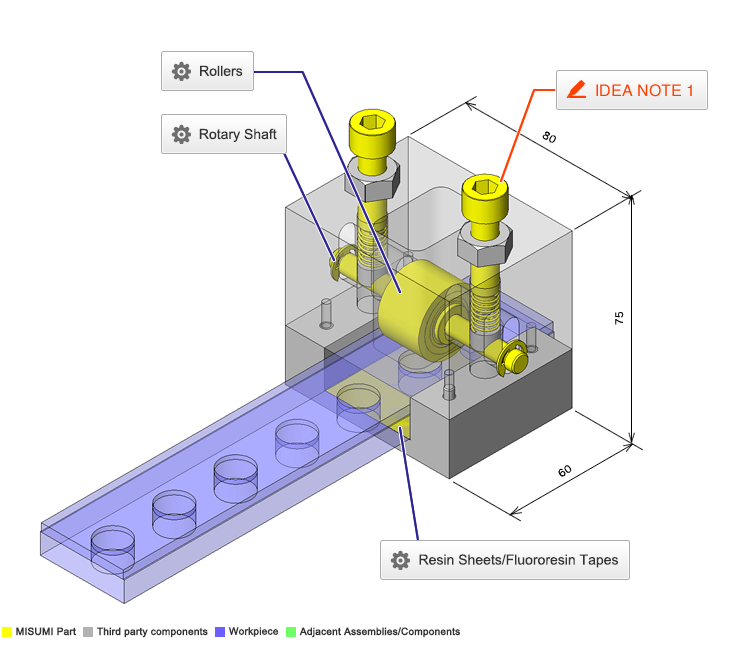

Vertically moves the shaft axis in the radial direction by utilizing springs to create a constant load.

Relevant category

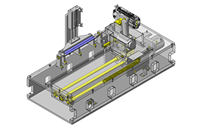

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

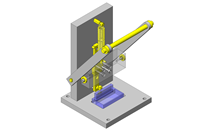

- A fitting/assembling jig that presses rubber workpieces into aluminum workpieces.

- Fits the convex portion of the rubber workpiece into the concave portion of the other workpiece.

Points for use

- A roller is used to press the parts together.

The fitting load is adjusted by screws.

Target workpiece

- External Dimensions

Workpiece (rubber): W40 x D4.0

Workpiece (aluminum): W41 x D10

Design Specifications

Operating Conditions or Design Requirements

- Outer dimensions: W80 x D60 x H75

- Maximum spring deflection: 8 mm

Required Performance

- The estimate for the required fitting force is 5N, but adjustments can be made if necessary.

Selection Criteria for Main Components

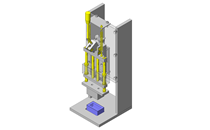

- Screws with dog point

- Screws with dog points and hex nuts are used to compress the springs and adjust the load.

Design Evaluation

Verification of main components

- Springs with the required force are selected.

- Fitting spring load

- Calculation formula: reaction force F = kx

- Number of springs used: 2

- Workpiece fitting load: F = 4.6 N x 2 = 9.2 N

- Assumed deflection during workpiece fitting: x = 4.7 mm (set length: 15.3 mm, free length: 20 mm)

- From k = F/x = 9.2/(4.7 x 2) = 0.98, springs with spring constant: k = 0.98 N/mm are selected.

Other Design Consideration

- Pressing with a roller prevents the load from being applied horizontally.

- Resin sheets are used to enhance the sliding property of the workpiece.

Explore Similar Application Examples

Page

-

/

-