(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- inCAD Library Home

- > No.000091 Large Automated Door

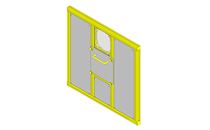

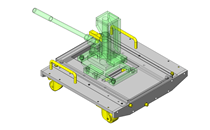

No.000091 Large Automated Door

23

23

A cylinder powered mechanism used to open a door.

Relevant category

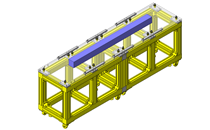

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

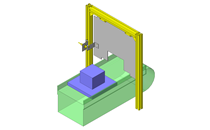

- Automated door with remote operation control center.

Points for use

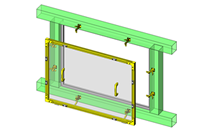

- Safety countermeasures such as safety fencing and remote door operation will be taken.

- Door open/close confirmation sensor is mounted above the door.

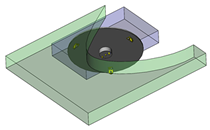

- The double door structure is operated by cylinders mounted on each side. Door swing angle is 90°.

Target workpiece

- Door size to accommodate people and material flow with sufficient clearance.

- External dims.: Up to W1800 x H2400mm can be loaded.

Design Specifications

Operating Conditions or Design Requirements

- A cylinder push/pull operates the door approx. 90° each side.

- External dimensions: W3086 x H2530 x D610 mm

Selection Criteria for Main Components

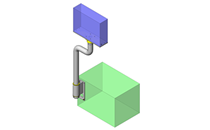

- Cylinder

- Select a size needed to open/close the door.

- Thrust bushings

- Thrust bushings that can support the entire weight of the door.

Design Evaluation

Verification of main components

- Verify that the cylinder has sufficient force to open/close the door.

- Cylinder

- Operating Conditions

W = 900N - door weight

d = 30mm - shaft dia.

μ = 0.5 -friction of coefficient ( shaft - oil free bushing)

L = 100mm - shortest distance from shaft to cylinder - Suppose the force to pull the door is Fp[N],

W × μ × (d / 2) = L × Fp

900 × 0.5 × 15 = 100 × Fp

Fp = 67.5N . . . ① - Determine cylinder output thrust (Fc)

Fc= η x P x d

η=0.5, Load factor

P=0.4MPa - Operating pressure

d - selected tube I.D. cross section

Fc=0.5 × 0.4MPa × π / 4× (100² - 30²)mm²

Fc=1429N > 67.5N (= From ①)

- Operating Conditions

- Thrust bushing

- Surface pressure applied per thrust bushing = (90kg x 9.8 / 4places) / (π / 4 × 50² -π / 4 × 30²) = 0.2N / mm² < 34.5N/mm²

(For surface pressure selected safety factor is 10)

- Surface pressure applied per thrust bushing = (90kg x 9.8 / 4places) / (π / 4 × 50² -π / 4 × 30²) = 0.2N / mm² < 34.5N/mm²

Other Design Consideration

Explore Similar Application Examples

Page

-

/

-

-

Relevant category

-

Relevant category