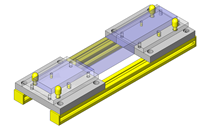

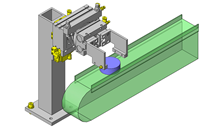

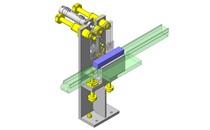

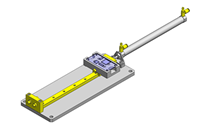

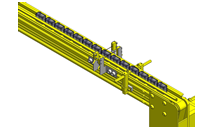

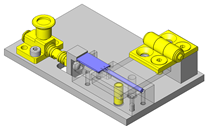

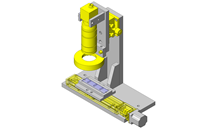

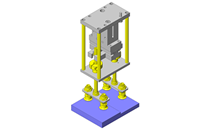

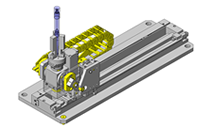

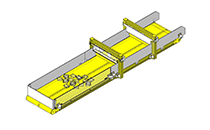

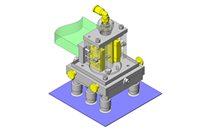

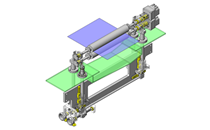

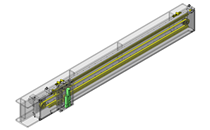

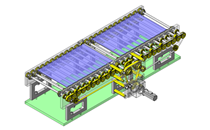

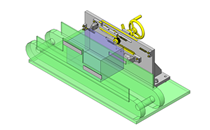

Miniature linear guide

| Product name | Miniature Linear Guides Standard Blocks, Light Preload, Precision Class L Configurable Type |

| Part number | SSE2B13-470 |

| Features | The most basic type among all the industry standard-compliant blocks. |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

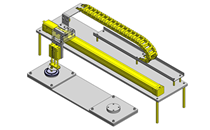

Linear guide is selected for accurate sliding.

Back to page top

Available sizes

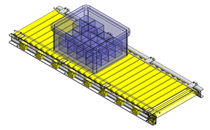

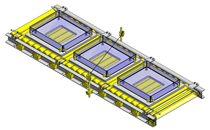

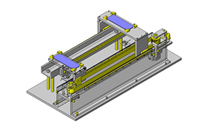

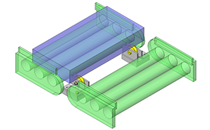

■Miniature linear guide (Standard block, Light preload, High grade, 2-blocks)

| Material | Hardness |

| Stainless steel (440C Stainless Steel) | 56HRC- |

| Carbon steel (SCM, etc. alloy) | 58HRC- |

| Overall height | Rail length |

| 6 | 70-100 |

| 8 | 70-130 |

| 10 | 75-275 |

| 13 | 95-470 |

| 16 | 110-670 |

| 20 | 160-700 |

Back to page top

Selection steps

■Miniature linear guide selection steps

- Determine the app. Conditions

- (Moving body speed, feed rate, motion pattern, Life)

↓

- Temporary selection of linear guide specifications

- (Temporarily select block type, height,

rail length based on the application condition)

↓

- Confirming basic safety

-

- Load capacity

- Life

- Preload

Back to page top

Accuracy Info

Preload and accuracy reference (Standard block · Light preload · High grade)

(μm)

| Radial clearance | -3~0 |

| Dimension tolerance of H | ±20 |

| Pair variation of H | 15 |

| Dimension tolerance of W2 | ±25 |

| Pair variation of W2 | 20 |

(μm)

| Rail length(mm) |

| -80 | 81-200 | 201-250 | 251-400 | 401-500 | 501-630 | 631-700 |

| Running parallelism | 3 | 7 | 9 | 11 | 12 | 13.5 | 14 |

Back to page top

Performance info.

Load rating of linear guides (Standard block ・Light preload ・High grade)

| Overall height | Basic load rating | Allowable static moment |

| C (Dynamic) kN | C0 (Static) kN | MA

N・m | MB

N・m | Mc

N・m |

| 6 | 0.3 | 0.6 | 0.8 | 0.8 | 1.5 |

| 8 | 0.9 | 1.5 | 4.1 | 4.1 | 5.2 |

| 10 | 1.5 | 2.5 | 5.1 | 5.1 | 10.2 |

| 13 | 2.2 | 3.3 | 8.8 | 9.5 | 16.1 |

| 16 | 3.6 | 5.4 | 21.6 | 23.4 | 39.6 |

| 20 | 5.2 | 8.5 | 48.4 | 48.4 | 86.4 |

Back to page top

Technical calculations

Linear guide life calculations

- Life

- When linear guides operate in linear motion while supporting loads, repeated stresses apply on the rolling elements (balls) and raceways (rails), eventually causing scale-like flaking due to material fatigue. The total run distance until this flaking appears is defined as linear guide's "Life".

- Rated life

- Rated life is a total distance 90% of linear guides reach without flaking when a group of the same guides are run under the same condition. The rated life can be calculated with basic dynamic load rating and the load applied on the guides as follows.

-

- When using linear guides, load calculations are initially needed. It is not easy to calculate the loads during linear motion due to vibrations and shocks, as well as load distribution on the guides. Furthermore, operating environment temperature has large effect on life. When these conditions are taken in consideration, the calculations would be as follows.

-

- L: Rated life (km)

- fH: Hardness factor (see Fig-1)

- fT: Temperature factor (see Fig-2)

- fC: Contact factor (see Table-1)

- fW: Load factor (see Table-2)

- C: Basic dynamic load rating (N)

- P: Applicable load (N)

- Hardness factor (fH)

-

In using linear guides, the shaft that balls contact must have sufficient hardness, If adequate hardness cannot be obtained, load rating decreases and life will be reduced as a result.

Please compensate the life value with the hardness factor.

- Temperature factor (fT)

-

When the temperature of linear guides exceed 100℃, hardness of blocks and rails will be reduced, causing reduction of life. Please compensate the life rating with temperature factor.

* Please use linear guides within the resistant temperature range on product pages.

- Contact factor (fC)

-

Table-1. Contact factor

Number of blocks installed on one rail and contact factor fC

| 1 | 1.00 |

| 2 | 0.81 |

| 3 | 0.72 |

| 4 | 0.66 |

| 5 | 0.61 |

In general, it is common to use 2 or more blocks on 1 rail. In such case, load applicable on each block would not be uniform due to machining variations. As the result, allowable load rating on each block would vary depending on the number of blocks used per rail. Please compensate the life rating with contact factor shown on Table-1.

- Load factor (fW)

-

Table-2. Load factor

| Application condition | fw |

No external shocks or vibrations and

speed is low 15m/min or less | 1.0-1.5 |

No significant shocks or vibration and

med. speed 60m/min or less | 1.5-20 |

External shocks and vibrations exist

and the speed is high 60m/min or over | 2.0-3.5 |

When calculating loads applicable on linear guides, other than the weight of the object, inertial force due to motion speeds, moment loads, and variations of each over time must also be obtained accurately. However, accurate calculation would be difficult due to repeated starts and stops and various shocks and vibrations. Therefore, the Load Factors shown in Table-2 are used to simplify the life calculations.

- Applicable load calculation method

- When moment loads apply a block, use the following formula to convert the moment load to applicable load.

-

- P: Applicable load (N)

- F: Downward load (N)

- C0: Static load rating (N)

- MA: Allowable static moment - Pitching direction (N・m)

- MC: Allowable static moment - Rolling direction (N・m)

- Lp: Load point distance (m) in pitching direction

- Lr: Load point distance (m) in rolling direction

Back to page top

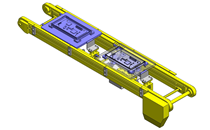

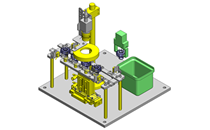

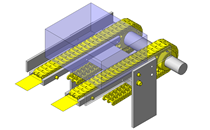

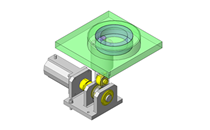

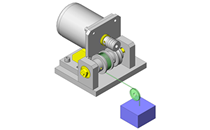

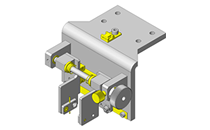

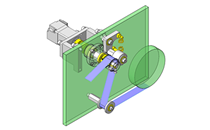

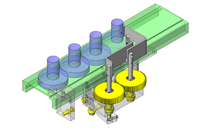

Ball plunger

| Product name | Ball Plungers -Roller- |

| Part number | BPRM6 |

| Features | The combination structure of the main ball and the sub ball facilitates smooth rotation of the ball. |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Popular item that is used as a means of table indexing and position retention.

Back to page top

Risk info.

Retaining force, durability

Back to page top

Available sizes

■Ball plunger (Roller type)

| Ball material | Body | Ball | Sub-ball | Spring | Usable temperature |

| Material | Material | Hardness | Material | Hardness | Material |

| Metal | 302HQ Stainless Steel | 440C Stainless Steel | 55HRC- | 440C Stainless Steel | 55HRC- | 631 Stainless Steel | −30〜100℃ |

| Resin | Polyacetal | − | −30〜80℃ |

■Sizes and Dimensions

| Thread DIA. (Coarse) | Ball | Body length |

| DIA. | Stroke |

| M6 | φ3 | 0.8 | 13 |

| M8 | φ4 | 1.3 | 15 |

| M10 | φ5 | 1.6 | 16 |

| M12 | φ7.1 | 2.3 | 20 |

| M16 | φ9.5 | 3.1 | 25 |

Back to page top

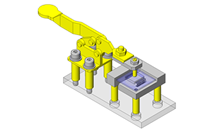

Mechanism Info.

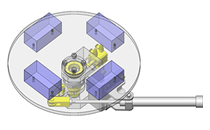

■Ball plunger (Roller type) structure explanation

The structure with sub-balls below the main ball allows for smooth main ball rotation.

Back to page top

Performance info.

■Spring load of ball plunger (Roller type) (N)

| Thread DIA. (Coarse) | Load (N) |

| min. | max. |

| M6 | 8.1 | 29.6 |

| M8 | 12.6 | 39.8 |

| M10 | 13.5 | 44.4 |

| M12 | 16.1 | 46.9 |

| M16 | 26.1 | 88.2 |

*Min. load is the initial load, max. is when the ball is depressed fully.

Back to page top

Back to page top

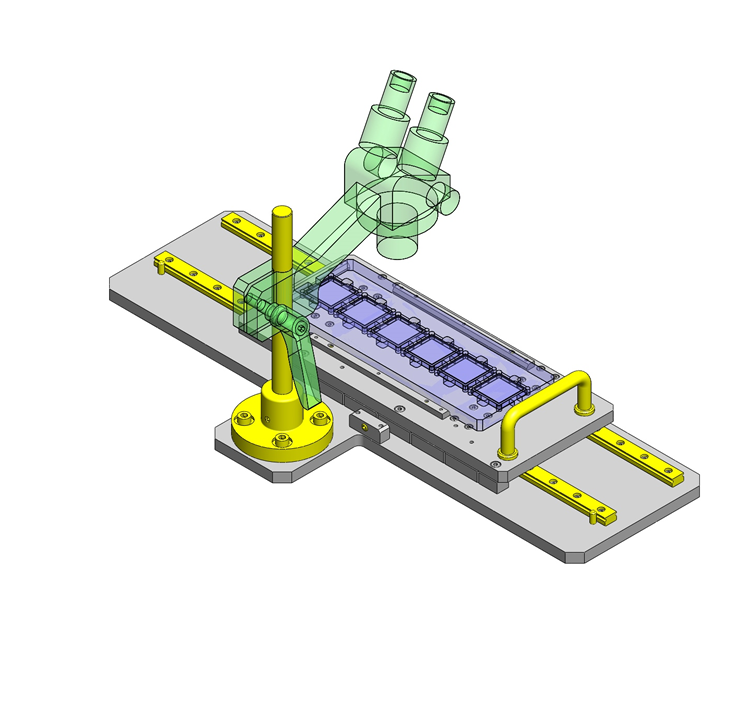

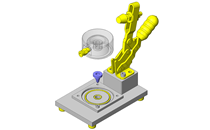

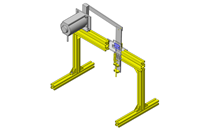

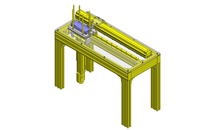

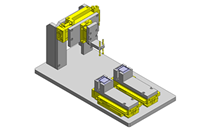

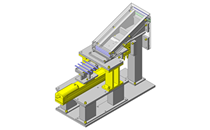

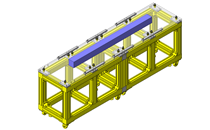

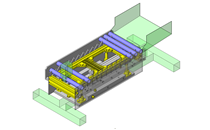

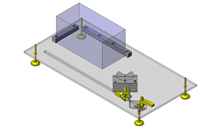

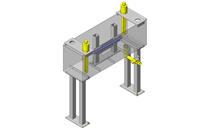

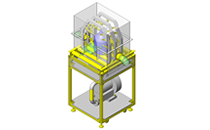

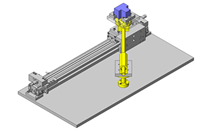

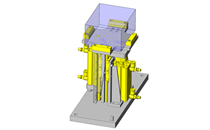

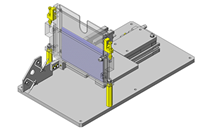

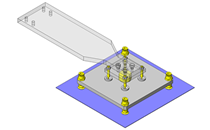

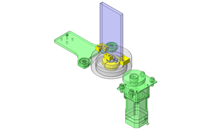

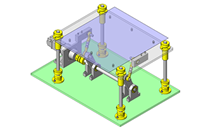

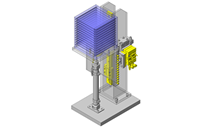

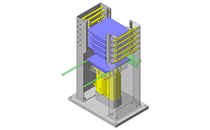

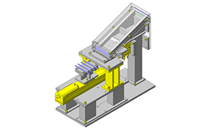

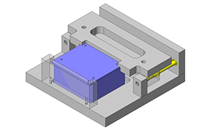

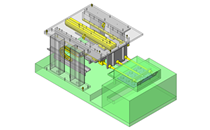

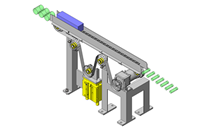

Devise stand

| Product name | Device Stands - Round Flanged, Pipe |

| Part number | SCSTN15-200 |

| Features | Stand Set of Low Cost and Standard Shape. |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Since vertical position can be adjusted easily where accuracy is not needed.

Back to page top

Available sizes

■Devise stand (Round flange, through hole type)

| Post | Bracket | Bracket |

| No dowel hole | With dowel hole |

| Material | Surface treatment | Material | Surface treatment | Post |

| Bar | Pipe | Bar | Pipe |

| 1045 Carbon Steel | − | Cast Iron Class No.35 | Black oxide

or

phosphate coating | ○ | ○ | ○ | ○ |

| 1045 Carbon Steel | Electroless nickel plating | ○ | ○ | ○ | ○ |

| 304 Stainless Steel | − | ○ | ○ | ○ | ○ |

| 1045 Carbon Steel | Electroless nickel plating | Electroless

nickel plating | ○ | ○ | − | − |

| 1045 Carbon Steel | ○ | ○ | − | − |

| 304 Stainless Steel | − | ○ | ○ | − | − |

(Induction hardening: 58HRC-, Depth 1.0 - 1.5)

■Sizes and Dimensions

| Post DIA. | Overall height | Flange O.D. | Flange height | Flange thickness | (Pipe I.D.) | (Dowel hole DIA.) |

| φ10 | 50-250 | φ56 | 35 | 12 | φ6 | φ6 |

| φ12 | 50-300 | φ68 |

| φ15 | 75-350 | φ75 | 40 | φ10 |

| φ20 | 75-400 | φ86 | 45 | 12 | φ11.7 |

| φ25 | 75-450 | φ100 | 50 | φ15.2 | φ8 |

| φ30 | 100-450 | φ106 | 60 | φ16 |

| φ35 | 125-500 | φ118 | 70 | 15 | φ20.1 | φ10 |

| φ40 | 150-500 | φ125 | 80 | φ22.7 |

| φ50 | 200-600 | φ140 | 100 | φ30.8 |

Back to page top

Accuracy Info

■Accuracy info. of devise stand (Round flange, through hole type)

| Post | Bracket | (Dowel hole) |

| O.D. | O.D. tolerance | Shaft bore DIA. | Bore DIA. tolerance | Hole DIA. | Hole DIA. tolerance |

| φ10 | -0.005/-0.014 | φ10 | +0.015/0 | φ6 | +0.012/0 |

| φ12 | -0.006/-0.017 | φ12 | +0.018/0 |

| φ15 | φ15 |

| φ20 | -0.007/-0.020 | φ20 | +0.021/0 |

| φ25 | φ25 | φ8 | +0.015/0 |

| φ30 | φ30 |

| φ35 | -0.009/-0.025 | φ35 | +0.025/0 | φ10 |

| φ40 | φ40 |

| φ50 | φ50 |

Back to page top

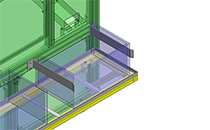

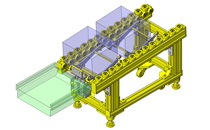

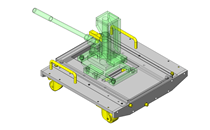

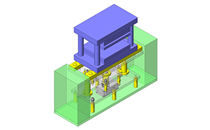

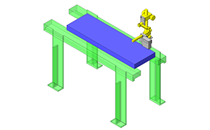

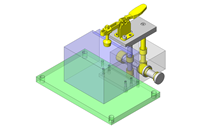

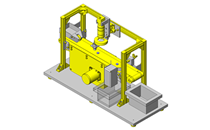

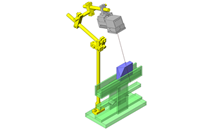

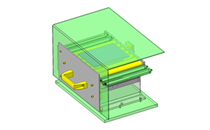

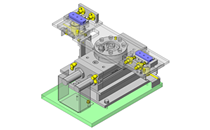

IDEA NOTE Devising of ball plunger engaging position

The mating part of the ball plunger has the notches located slightly lower than the center of the parts height. Regardless of heat treating, when the notches are worn, this part can be turned upside down (use locating dowel pins, etc. to ensure the repeatability) to regain the initial condition.

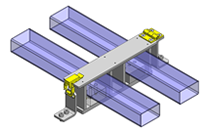

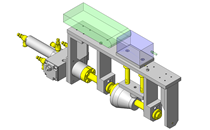

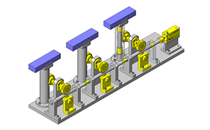

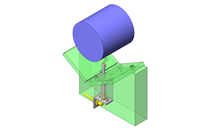

IDEA NOTE Dual role pins

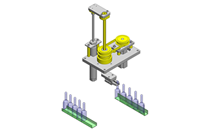

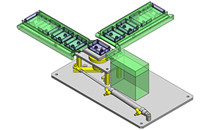

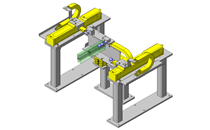

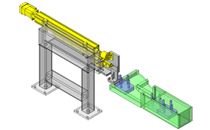

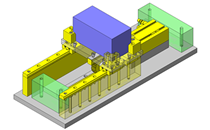

Locating pins are used to locate the linear guide rail, to prevent the block from falling off.