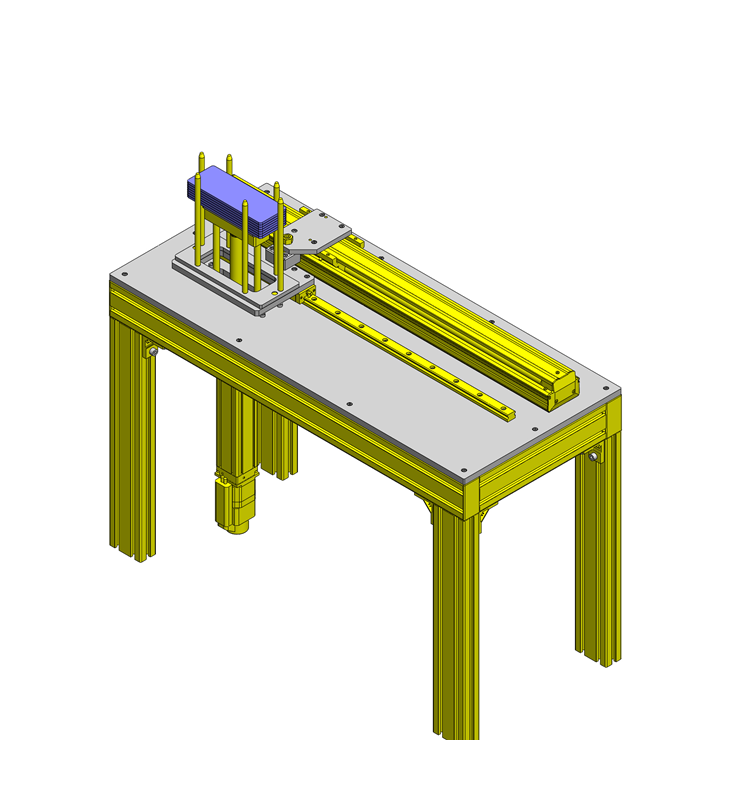

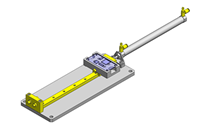

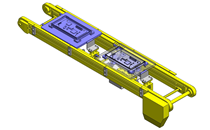

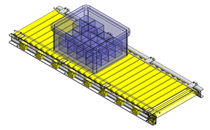

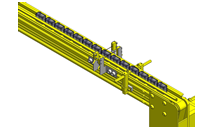

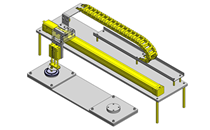

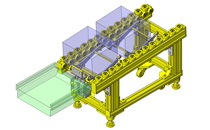

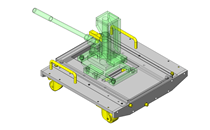

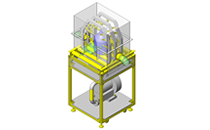

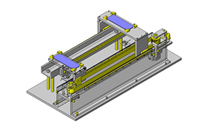

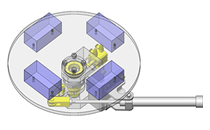

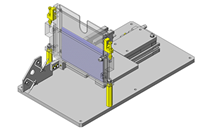

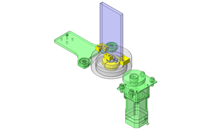

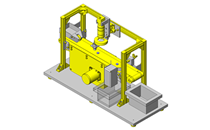

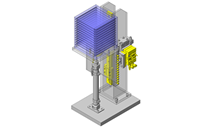

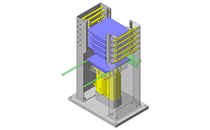

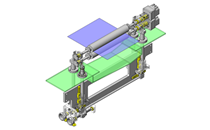

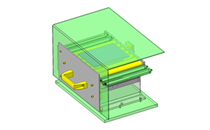

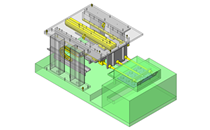

Single axis robot Slider type

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Linear motion unit that satisfies load capacity, stroke, and motion speed requirements.

Back to page top

Risk info.

Disconnection

Back to page top

Available sizes

Single axis robot (RSH3, Slider type)

General specifications

| Ball screw | Motor | Position detector | Operating atmosphere

temp. ・ humidity | Controller

power input |

φ15

(C7 Rolled) | AC Servo motor

100W | Resolver | 0?40℃・35?85%RH

(No condensation) | AC100-115V

AC200-230V |

Basic specifications

Lead

(mm) | Stroke

(mm) |

| 5 | 150-1050

(50Increment) |

| 10 |

| 20 |

Dimensions ・ Mass

| Dimensions ・ Mass | Stroke |

| 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 |

| Overall length | 518 | 568 | 618 | 668 | 718 | 768 | 818 | 868 | 918 | 968 |

| Mass(kg) | 4.7 | 5 | 5.3 | 5.6 | 5.9 | 6.2 | 6.6 | 6.9 | 7.2 | 7.5 |

| Dimensions ・ Mass | Stroke |

| 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 |

| Overall length | 1018 | 1068 | 1118 | 1168 | 1218 | 1268 | 1318 | 1368 | 1418 |

| Mass(kg) | 7.8 | 8.1 | 8.4 | 8.7 | 9 | 9.3 | 9.7 | 10 | 10.3 |

Back to page top

Selection steps

Single axis robot selection steps

Load capacity

↓

Stroke

↓

Cycle time or Max. Speed

↓

Detail confirmation

Back to page top

Accuracy Info

Accuracy of Single Axis Robot

Repeatability: ±0.01mm

Back to page top

Performance info.

Basic specifications

Lead

(mm) | Max. load capacity | Rated force

(N) | Max. speed

(mm/sec) | Rated

Life |

| Horizontal (kg) |

| 5 | 80 | 339 | 300-105 | 10,000km

or more |

| 10 | 60 | 169 | 600-210 |

| 20 | 30 | 84 | 1200-420 |

Max. speed(mm/sec)

Lead

(mm) | Stroke |

| 150-600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 |

| 5 | 300 | 255 | 225 | 195 | 180 | 165 | 150 | 135 | 120 | 105 |

| 10 | 600 | 510 | 450 | 390 | 360 | 330 | 300 | 270 | 240 | 210 |

| 20 | 1200 | 1020 | 900 | 780 | 720 | 660 | 600 | 540 | 480 | 420 |

Back to page top

Technical information

Convenient sizing software is available to use.

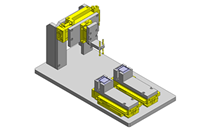

■ Single axis robot selection (WEB design support service)

Back to page top

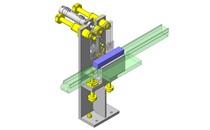

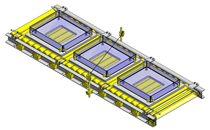

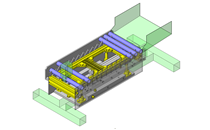

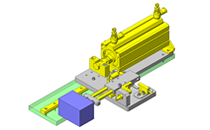

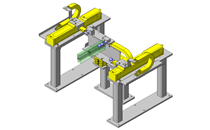

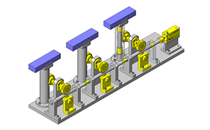

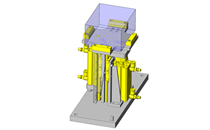

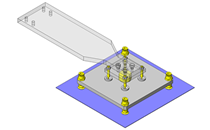

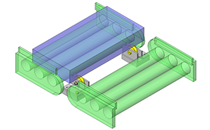

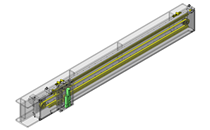

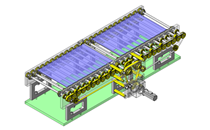

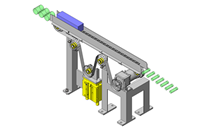

Linear guide

| Product name | Linear Guides - Heavy Load |

| Part number | SX2R28-760 |

| Features | Compliant with the industry standard specifications. |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Suitable for linear guidance and as a load support.

Back to page top

Available sizes

Linear guide (For heavy loads ・ Normal clearance, Standard grade ・ 2 blocks ・ Standard blocks)

| Material | Hardness | Overall height | Rail length |

Carbon steel

(SCM etc. alloy steel) | 58HRC~ | 24 | 160-1480 |

| 28 | 220-1960 |

| 33 | 220-1960 |

Back to page top

Selection steps

Linear guide selection steps

- Determine application conditions

- (Mass of moving body, Feed rate, Motion pattern, Life)

↓

- Interim selection of linear guide specifications

- (Temporarily select block type, height,

rail length based on the application condition)

↓

- Confirm basic safety

-

- ● Load capacity

- ● Life

- ● Preload

Back to page top

Accuracy Info

Preload and accuracy standards

(μm)

| Tolerance of H | ±100 |

| Pair variation of H | 20 |

| Tolerance of W2 | ±100 |

Pair variation

of W2 | H24・28 | 20 |

| H33 | 30 |

(μm)

| Rail length |

| -250 | 251-400 | 401-500 | 501-630 | 631-800 | 801-1000 | 1001-1250 | 1251-1600 | 1601-2000 |

| Running parallelism | 7 | 12 | 14 | 18 | 21 | 23 | 25 | 27 | 28.5 |

Back to page top

Performance info.

Linear guide load rating (For heavy loads ・ Normal clearance ・ Standard grade)

| Overall height | Basic load rating | Allowable static moment |

| C (Dynamic) kN | C0 (Static) kN | MA・MB

N・m | Mc

N・m |

| 24 | 8.6 | 14.2 | 69 | 98 |

| 28 | 12.5 | 21.3 | 155 | 232 |

| 33 | 20.2 | 34.5 | 275 | 393 |

Back to page top

Technical calculations

Linear guide life calculations

- ●Life

- When linear guides operate in linear motion while supporting loads, repeated stresses apply on the rolling elements (balls) and raceways (rails), eventually causing scale-like flaking due to material fatigue. The total run distance until this flaking appears is defined as linear guide's "Life".

- ●Rated life

- Rated life is a total distance 90% of linear guides reach without flaking when a group of the same guides are run under the same condition. The rated life can be calculated with basic dynamic load rating and the load applied on the guides as follows.

-

- When using linear guides, load calculations are initially needed. It is not easy to calculate the loads during linear motion due to vibrations and shocks, as well as load distribution on the guides. Furthermore, operating environment temperature has large effect on life. When these conditions are taken in consideration, the calculations would be as follows.

-

- L: Rated life (km)

- fH: Hardness factor (see Fig-1)

- fT: Temperature factor (see Fig-2)

- fC: Contact factor (see Table-1)

- fW: Load factor (see Table-2)

- C: Basic dynamic load rating (N)

- P: Applicable load (N)

- Hardness factor (fH)

-

In using linear guides, the shaft that balls contact must have sufficient hardness, If adequate hardness cannot be obtained, load rating decreases and life will be reduced as a result.

Please compensate the life rating with hardness factor.

- Temperature factor (fT)

-

When the temperature of linear guides exceed 100℃, hardness of blocks and rails will be reduced, causing reduction of life. Please compensate the life rating with temperature factor.

* Please use linear guides within temperature shown on product pages.

- Contact factor (fC)

-

Table-1. Contact factor

Number of blocks installed on one rail and contact factor fC

| 1 | 1.00 |

| 2 | 0.81 |

| 3 | 0.72 |

| 4 | 0.66 |

| 5 | 0.61 |

In general, it is common to use 2 or more blocks on 1 rail. In such case, load applicable on each block would not be uniform due to machining variations. As the result, allowable load rating on each block would vary depending on the number of blocks used per rail. Please compensate the life rating with contact factor shown on Table-1.

- Load factor (fW)

-

Table-2. Load factor

| Application condition | fw |

No external shocks or vibrations and

speed is low 15m/min or less | 1.0-1.5 |

No significant shocks or vibration and

med. speed 60m/min or less | 1.5-20 |

External shocks and vibrations exist

and the speed is high 60m/min or over | 2.0-3.5 |

When calculating loads applicable on linear guides, other than the weight of the object, inertial force due to motion speeds, moment loads, and variations of each over time must also be obtained accurately. However, accurate calculation would be difficult due to repeated starts and stops and various shocks and vibrations. Therefore, the Load Factors shown in Table-2 are used to simplify the life calculations.

- Applicable load calculation method

- When moment loads apply a block, use the following formula to convert the moment load to applicable load.

-

- P: Applicable load (N)

- F: Downward load (N)

- C0: Static load rating (N)

- MA: Allowable static moment - Pitching direction (N・m)

- MC: Allowable static moment - Rolling direction (N・m)

- Lp: Load point distance (m) in pitching direction

- Lr: Load point distance (m) in rolling direction

Back to page top

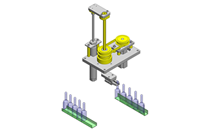

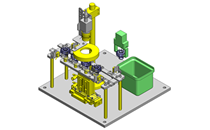

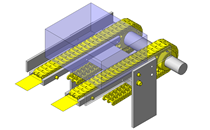

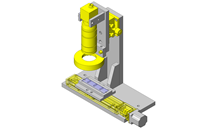

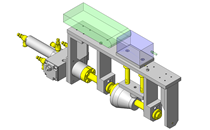

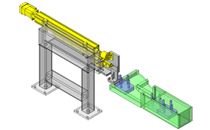

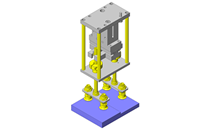

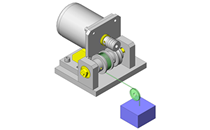

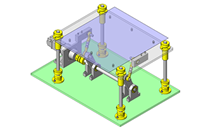

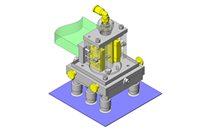

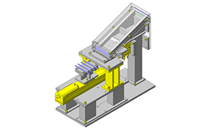

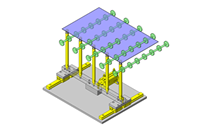

Cam follower

| Product name | Cam Followers - Hex Hole, No Seal, Crown Type |

| Part number | CFUA12-30 |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Suitable for supporting linear transfer.

Back to page top

Available sizes

Cam follower (Crowned with a hex socket)

| Purpose | Main body | Nut |

| Material | Seal | Material | Surface treatment |

| No | Yes |

| General | 52100 Bearing Steel | ○ | ○ | 1045 Carbon Steel | Black oxide |

| 440C Stainless Steel | ○ | ○ | 304 Stainless Steel | - |

| Low particle generation | - | ○ |

| Heavy load | 52100 Bearing Steel | - | ○ | 1045 Carbon Steel | Black oxide |

| Stud DIA. | Thread | Outer race diameter | Outer race width | Overall length |

| φ8 | M8x1.25 | φ19 | 11 | 32 |

| φ10 | M10x1.25 | φ22 | 12 | 36 |

| φ26 |

| φ12 | M12x1.5 | φ30 | 14 | 40 |

| φ32 |

| φ16 | M16x1.5 | φ35 | 18 | 52 |

Accuracy Info

Cam follower accuracies

Stud diameter tolerance: h7

Outer ring DIA. Tolerance: 0/-0.05

Outer race DIA. Tolerance: 0/0.12

Performance info.

Cam follower reference data

Stud DIA.

-Outer race diameter | General |

Basic dynamic

load rating C(kN) | Basic static

load rating Cor(kN) | Max allowable

load(kN) | Track load capacity

(Crowned)(kN) | Rotational speed limit (rpm) |

| With Seal | Without Seal |

| 8-19 | 4.17 | 4.65 | 4.73 | 1.37 | 14000 | 20000 |

| 10-22 | 5.33 | 6.78 | 5.81 | 1.67 | 11900 | 17000 |

| 10-26 | 2.06 |

| 12-30 | 7.87 | 9.79 | 9.37 | 2.45 | 9800 | 14000 |

| 12-32 | 2.74 |

| 16-35 | 12.00 | 18.30 | 17.30 | 3.14 | 7000 | 10000 |

Stud DIA.

-Outer race diameter | Heavy load |

Basic dynamic

load rating C(kN) | Basic static

load rating Cor(kN) | Max allowable

Load(kN) | Track load capacity

(Crowned)(kN) | Rotational speed limit (rpm) |

| With Seal |

| 8-19 | 8.13 | 11.20 | 4.73 | 1.37 | 3480 |

| 10-22 | 9.42 | 14.30 | 5.81 | 1.67 | 2880 |

| 10-26 | 2.06 |

| 12-30 | 13.40 | 19.80 | 9.37 | 2.45 | 2320 |

| 12-32 | 2.74 |

| 16-35 | 20.60 | 37.60 | 17.30 | 3.14 | 1800 |

Back to page top

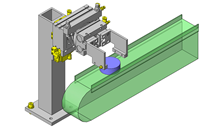

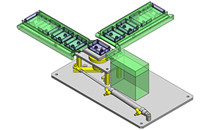

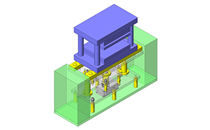

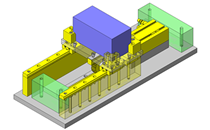

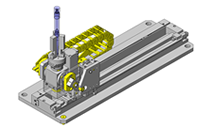

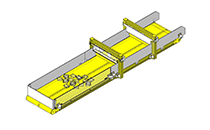

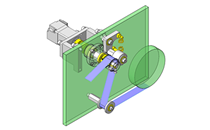

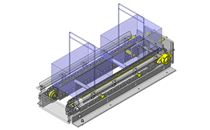

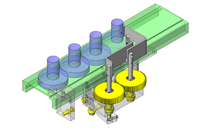

IDEA NOTE Devising of workpiece guides

The surface of the workpiece guides will need to be both smooth and hard. Linear Shafts has both of these characteristics, and is fully configurable Misumi product.

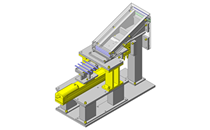

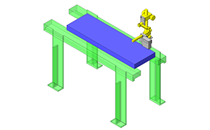

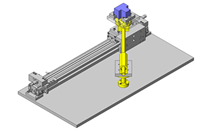

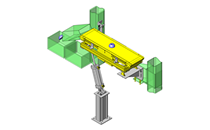

IDEA NOTE Floating mechanism

The connection between robot and slide table is floating structure utilizing cam follower.