(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- inCAD Library Home

- > No.000237 Cylindrical Sheet Heat Welding

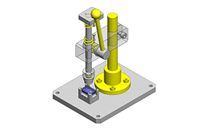

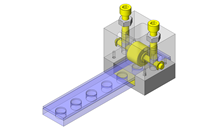

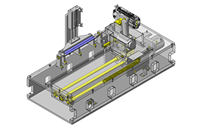

No.000237 Cylindrical Sheet Heat Welding

13

13

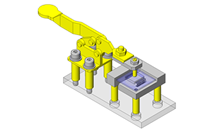

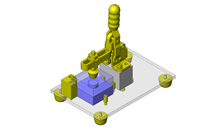

Retains workpiece using vacuum suction.

Relevant category

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

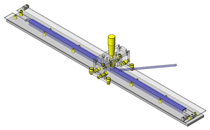

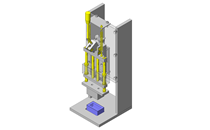

- A device designed to hold a resin sheet in a cylindrical shape while the overlapping portions are being heat welded together.

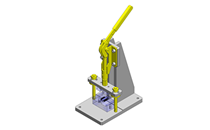

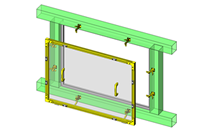

- Welding unit only advances from protective cover when buttons on each side of the unit are pressed simultaneously.

- An indexing plunger is used to fix the rotary table into position.

Points for use

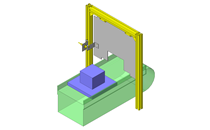

- The resin work piece is placed manually.

- Once workpiece is in position, the indexing plunger rotates the workpiece into welding position.

- After the welding mechanism unit is retracted, the workpiece is removed from the top.

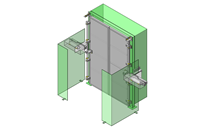

- To prevent malfunctions and enhance safety, an area sensor is installed. Another safety measure is the welding unit will not emerge or heat until two buttons outside the workspace are pressed.

Target workpiece

- Resin sheet

- Outer dimensions: W335 x D405 x t0.1mm

- Weight: 18g

Design Specifications

Operating Conditions or Design Requirements

- Air cylinder stroke amount: 100mm

<Maximum stroke amount: 100mm> - Outer dimensions

W650xD675xH658mm

Required Performance

- Cylinder thrust: 11.8N or higher

Selection Criteria for Main Components

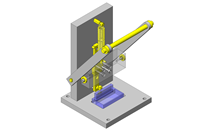

- Air cylinder

- A compact cylinder is selected to save space.

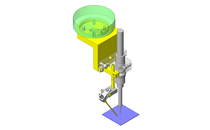

- Cartridge Heaters

- A long cartridge heater that satisfies the heat quantity requirement for heat welding is selected.

Design Evaluation

Verification of main components

- Cylindrical thrust is verified based on the workpiece load and the heat quantity required of the heater is verified based on the heating conditions.

- Cylinder

- Conditional value: mass to move: m = 4kg, friction coefficient μ = 0.3, load factor η = 0.5 (from catalog), outstroke pressure area A1 = 1256mm² (from catalog), operating pressure P = 0.4MPa

- Load applied to cylinder: F = mgμ, hence, F = 4 x 9.8 x 0.3 = 11.8N,

- Cylinder output F1 = load factor x outstroke pressure area x operating pressure, hence, F1 = 0.5 x 1256 x 0.4 = 251.2N

-> Safety factor: F1/F = 251.2/11.8 ≈ 21

- Heat quantity required of the heater

- Conditional value: mass of heated workpiece: 0.585kg (A5052), specific heat of heated workpiece: 0.23kcal/kg°C, temperature rise: 190°C (heating until the temperature of heated workpiece reaches 210°C), heating time: 0.25h (idling), heating time: approx. 3 sec (workpiece), efficiency: 0.3 (standard specification: from catalog)

- The workpiece heating time should be determined through trial and error because it depends on the size, thickness, and material of the workpiece.

- Heat quantity required of heater H (kw) = mass of heated workpiece (kg) x specific heat of heated workpiece (kcal/kg°C) x temperature rise (°C)/(860 x heating time (h) x efficiency (η)), hence

H = 0.585 x 0.23 x 190/(860 x 0.25 x 0.3) = 0.396kW = 396W

Other Design Consideration

- For safety the heater is inside the cover except during welding.

- To prevent injuries, the buttons to operate the heating element are placed outside the work space.

- During work piece placement, wrap the work piece on revolution along the groves of the suction block, confirm the overlap is 5mm, and then manually rotate the suction block to the welding the position and fix into place with the plunger.

- The material and shape of the welding portion are determined through trial and error. Each work piece will be different and depends of the material, thickness, and shape.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category